Search Results

Showing 11 – 20 of 453 results

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Induction-heated thermocompression press developed collaboratively by Roctool and CEA-Liten has verified improvement in temperature and pressure conditions, opening up new opportunities.

Use of recycled carbon fiber and bioresins aim to reshape the future of photovoltaic energy and mobility.

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

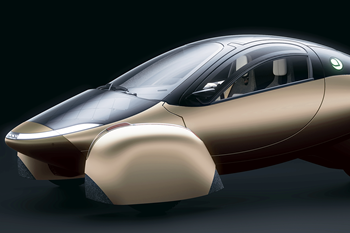

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

The UAE will provide an ideal environment to introduce the company’s solar-powered composites-intensive BinC vehicle internationally.

Kerberos Engineering uses TeXtreme 0/90 woven fabrics for satellite solar array manufacturing, cutting weight and onboard resources, enhancing structural integrity and streamlining production.

Innovative yacht manufacturer will use flax fiber-reinforced bio-based or recyclable resin to improve vibration damping, aesthetics and sustainability for its new 100 Sunreef Power cats.

Financial investments, R&D facility inauguration and an operational solar power plant expands the French company’s product developments, operational recycling capacity and reduce its CO2 footprint.

NASA ACS3 system made of flexible polymer and carbon fiber materials has successfully deployed its boom system, shows potential for future space operations.

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.