Search Results

Showing 1 – 10 of 249 results

Per a long-term agreement, space-qualified carbon fiber/epoxy materials will be delivered to Airborne for high-volume production of solar array substrates and yoke panels.

Airborne Aerospace will manufacture more than 700 composite substrate panels and yoke substrates for Airbus Sparkwing solar arrays, a critical component of MDA Space’s Aurora satellite product line.

Airborne, with the help of partners, designed, manufactured and assembled two 6-meter-diameter mirror support structures for highly complex scientific telescope project.

Event featured insights from project partners regarding novel materials testing, addressing technical challenges and the path to certification to better understand AWE systems and their potential.

Airborne delivered two mirror support structures for the FYST and SOLAT telescopes, assembling 26,300 components while maintaining near-zero CTE, strict tolerances on 6.5 × 6.5 × 1.8-meter assemblies.

Commemorating the theme “Performance With Purpose,” CW has gathered key stories over the last year that exemplify how composites have progressed aviation, AAM and defense.

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

Airborne’s capabilities will support airframe prototyping, automated production of the Limosa LimoConnect eVTOL + eCTOL aircraft from prototype through to serial production to help meet 2028 entry-into-service goals.

CAMX 2025: C.R. Onsrud reinforces its ability to produce well-engineered, durable CNCs for composites machining with the Q-Series.

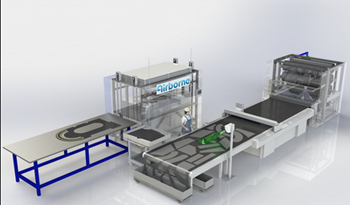

Airborne’s Automated Ply Placement and Automated Edge Sealing technologies aim to ensure constant, repeatable and flexible production of complex composite products.