Airborne to supply composites cutting/kitting equipment to Airbus Helicopters

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

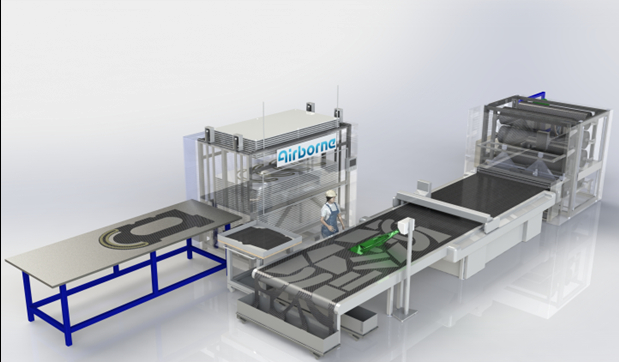

Kit by Light system. Source | Airborne

Airborne (The Hague, Netherlands) has been selected by (Marignane, France and Donauwörth, Germany) to renew the aerospace company’s cutting room in Donauwörth with Airborne’s state-of-the-art digital . The main objective is to improve operation and material efficiency by making composite plies kitting faster, easier and without mistakes.

The new cutting and kitting lines will include full digital control of the total kitting process to guarantee flexibility, 100% quality control (zero mistakes), enable dynamic nesting combining multiple parts in a nest and provide more output per cutter and per worker. The full workflow will be digital and seamlessly integrated, from work preparation to execution on the shop floor.

In this project, Airborne’s Kit by Light system will be tailored to meet Airbus Helicopters’ requirements, tested and installed in the factory before delivery. The systems support the operator with a digital light system for picking, sorting and sequencing of plies.

Airborne uses Automated Programming in all its machines, which avoids the need for programming the system. The software takes the nest, kit and material input, and translates this via an advanced algorithm into the correct instructions for the operator to offload the cutter, to make kits with plies in the correct sequence and to store them in the dynamic buffer. This happens on the fly, which Airborne says makes it easy to implement on the shop floor.

This approach of software-driven automation makes the systems flexible. The user can easily upload new kits and nest files, including a mix of parts, and the system will adapt all the instructions for the operator automatically. It provides the customer with the possibility to adapt to changing operational needs (for example, by using dynamic nesting) or to new product designs.

“We are thrilled to be selected by Airbus Helicopters,” says Marcus Kremers, CTO of Airborne. “It’s an exciting and top-level customer, with a great team of engineers that we are happy to work with. The Kit by Light system is a good example of how digital automation can reduce material waste and improve operational efficiency.”

In May 2023, Airborne was also selected to provide Airborne with an automated ply placement system for the A350.

Related Content

-

Composite cutting systems are dedicated to material optimization

CAMX 2024: FKgroup showcases its solutions for cutting composite materials, focusing on sustainability and efficiency.

-

Cold cutting equipment designed for carbon fiber

CAMX 2024: Sheffield, a producer of highly accurate cutting machines, highlights its C-503 model machine made to cut carbon fiber, fiberglass and even natural fibers.

-

Aitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.