WH Lipex introduces single fiber applicator for glass fiber sizing implementation

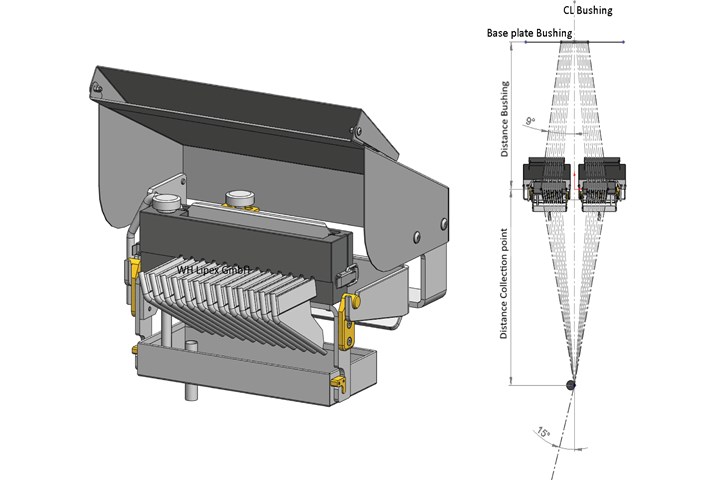

Coating module individually displays glass fibers for complete fiber wetout and improved bonding capabilities.

Photo Credit: WH Lipex

(Munich, Germany) part of Woollard & Henry Group (Aberdeen, U.K.) and a fiberglass technology company, introduces the single fiber applicator, a coating module that enables manufacturers to apply sizing to individual glass fiber strands.

Fibers are no longer in bundles, but are instead individually displayed, ensuring all individual filaments are better enclosed with wetting additive. This performance is said to significantly increases the sizing amount on the fibers, improving their bonding capabilities.

Further, WH Lipex says the applicator’s main advantages include increasing the end product’s mechanical properties, thus offering new possibilities for weight and cost reduction.

Related Content

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

ORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.