PRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

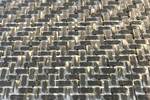

Component made with RFA570 adhesive film. Source | PRF Composite Materials

After two years of launching prepreg products, PRF Composite Materials (Poole, Dorset, U.K.) is introducing a new suite of primer and adhesive films, starting with its new RFA570 eXpress cure adhesive film and RF Primer.

RFA570 has been principally designed for use with RP570 and RP570 FR eXpress cure epoxy prepregs, as an adhesive for core bonding applications. The distinctive characteristics of this product enable it to be cured in a press in 4 minutes at 140°C, thereby speeding up the processing of Nomex or aluminum honeycomb sandwich panels. The adhesive film will also cure in autoclave, with a typical curing cycle of 4 minutes once the tool temperature has stabilized at 140°C. It is fully compatible with PRF’s full range of epoxy prepreg systems.

Formulated as an epoxy-based composite primer/surfacing film, PRF’s new RF Primer film is fully compatible with the company’s epoxy prepreg systems and provides a sacrificial surface that enables the constructor to eliminate paint priming. The film is laid as a first layer and then backed up with a prepreg laminate. It will fully co-cure with PRF epoxy prepreg formulations and will reduce the time required for surface preparation, thereby reducing cost per part.

The PRF team says it will be launching further film and prepreg products over the coming year.

Related Content

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.