Graphene-enhanced prepreg launched for lightning strike protection

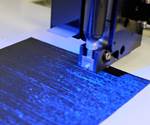

Haydale's range of graphene-enhanced prepreg materials utilize functionalized nanomaterials to improve the electrical conductivity in aerospace applications.

Source | Haydale

Haydale (Ammanford, U.K.) has launched a range of graphene-enhanced prepreg material for lightning strike protection, utilizing functionalized nanomaterials to improve the electrical conductivity. The material can be used for structural components or for enclosures for electronic avionics systems.

According to Haydale, the material also has potential applications for unmanned aerial vehicles (UAV), commercial aviation or space applications, or offshore wind turbine blades.

The material has been developed in collaboration with Airbus UK (Bristol), BAE Systems (Farnborough, U.K.), GE Aviation (Evendale, Ohio, U.S.) and Element Materials Technology Warwick Ltd. (Warwick, U.K.), within the U.K.’s National Aerospace Technology Programme (NATEP)-supported GraCELs 2[1] project, where the first iterations of materials were developed and subjected to lighting strike tests. The consortium is now looking to manufacture a demonstrator component using the developed materials to establish composite manufacturing protocols for commercial purposes.

An electrically conductive masterbatch is also commercially available, and the Haydale team has been working with customers to test the capability achieving significant results over existing materials.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

VoxelMatters report reveals top companies in composites AM

The new market study identifies key players in a $785 million global market that has grown by 21% year on year.

-

KCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

.jpg;width=70;height=70;mode=crop)