CactuX in-situ BOX simulates real-life conditions of composite samples during CT analysis

The autonomous in-situ BOX combines the environment temperature control function and power supply function, enabling new possibilities for material and internal structure research.

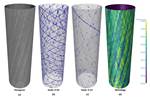

In-situ BOX for μCT stations for real-life conditions simulation (left) and a computed tomography (CT) scan example (right). Source (All Images) | CactuX

CactuX (Lelekovice, South Moravia, Czech Republic), a technological company developing and producing solutions in the field of X-ray nondestructive testing (NDT), is focused on providing a versatile computed tomography (CT) service as well as smart solutions for CT systems for composite materials through its latest product, in-situ BOX.

X-ray technologies, particularly CT, offers the ability to visualize and quantify complex internal structures in full 3D, without altering or damaging the composite part, CactuX explains. Its versatility can also help improve product performance, reduce scrap and speed up development cycles, for finished parts, prototypes or in situ testing under thermal or mechanical load. This makes CT an invaluable tool throughout the product life cycle, from R&D to process optimization, quality assurance and failure analysis, whether working with fiber-reinforced, particle-reinforced, multilayered composites or nanocomposites.

is reported to take regular CT measurement and analysis even further — it is possible to monitor the sample structure and behavior under different conditions, so called “in-situ analysis.”

In-situ CT imaging is a scanning technique that is performed while the sample is being subjected to controlled conditions, such as mechanical loading (tension, compression, bending), thermal cycles (heating, cooling) and electrical or environmental exposure (humidity, battery cycling). The goal is to observe and quantify how the internal structure of the material evolves in real time, under conditions that simulate actual service environments.

X-Ray CT is used for in situ inspection of a ceramic matrix composite (CMC) under load. Progressive damage accumulation is detected on a sub-surface plane of the CMC, applied 25%, 50%, 75% and 100% of maximum Pmax. .

Composite materials often exhibit failure mechanisms like delamination, fiber breakage, matrix cracking or interfacial debonding. These flaws may develop below the surface and progress over time. CactuX believes its technology opens the door to new levels of understanding in composites behavior, enabling engineers and researchers to validate simulation models, optimize material design and fine-tune production parameters.

CactuX offers two standardized types of in-situ BOXes: a thermal BOX for simulating temperature variations around the sample, and a battery BOX designed for simulating battery life cycle cycling, including temperature control. Additionally, the in-situ BOXes can be customized to meet specific customer requirements, such as integrating power supply options, temperature regulation or mechanical stress simulation.

Related Content

-

Mechanical testing of ceramic matrix composites

Today’s CMC materials, robust and resistant to high temperatures, provide their own set of challenges when determining their performance through mechanical testing.

-

Embraer conducts composite structural wing testing for PDNT

New technologies demonstration platform (PDNT), validating innovative processes, methodologies and new materials, exceeded more than 200% of expected progressive load limit.

-

Carbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.