TPRC project to develop structural analysis capabilities for overmolded parts

The ThermoPlastic composites Research Centre is working to develop an optimal process window for overmolding for both aerospace and automotive materials.

Source | TPRC

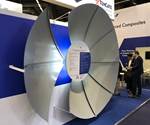

The ThermoPlastic composites Research Centre (TPRC, Enschede, the Netherlands) has announced it is currently finalizing its second project on overmolding, which will develop structural analysis capabilities for overmolded parts.

The process is simulated by combining AniForm’s (Enschede, the Netherlands) forming software and Autodesk’s (San Rafael, Calif., U.S.) Moldflow injection molding software with structural analysis software from Abaqus. A new geometry has been realized to characterize the interface under different loading conditions, which provides the input data to predict part performance in terms of stiffness and strength in the simulation. The research center says a new technology demonstrator has been developed.

The follow-up project on overmolding will start in October 2019 and will continue the organization’s work on structural analysis by developing an optimal process window for overmolding for both aerospace and automotive materials. In this multilateral project, external partners may join the project in addition to the TPRC members who are involved.

Related Content

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

First Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.