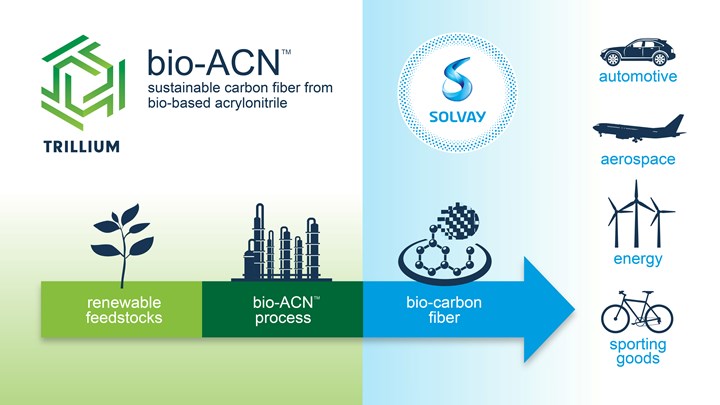

Solvay collaborates with Trillium on bio-based acrylonitrile for carbon fiber applications

New agreement with Trillium Renewable Chemicals will enable Solvay's development of sustainable, bio-carbon fiber for use in various applications.

Photo Credit: Solvay, PR018

Solvay (Brussels, Belgium) and (Knoxville, Tenn., U.S.) have signed a letter of intent to develop the supply chain for bio-based acrylonitrile (bio-ACN). Trillium will supply Solvay with bio-ACN from Trillium’s planned commercial asset, and Solvay will evaluate bio-ACN for carbon fiber manufacturing as part of its long-term commitment to developing . The aim of this partnership is to produce carbon fiber for use in various applications such as aerospace, automotive, energy and consumer goods.

“Trillium’s bio-ACN process technology enables bio-carbon fiber,” explains Corey Tyree, CEO of Trillium. “We are excited to continue our partnership with Solvay, who have supported the bio-ACN process technology development since 2014. Solvay is a leader in the most rapidly-growing acrylonitrile segment [carbon fiber] and are market leaders in bio-carbon fiber and sustainable development.”

Acrylonitrile is a chemical intermediate typically made from petroleum-based feedstocks like propylene, and is the primary raw material used in the production of carbon fiber. Trillium’s Bio-ACN process delivers acrylonitrile from plant-based feedstocks, such as glycerol, with a lower carbon footprint.

“We are thrilled to be partnering with Trillium which aligns well with our Solvay One Planet commitment to more than double our revenue based on renewable or recycled materials by 2030,” comments Stephen Heinz, head of composite research and innovation, Solvay. “Innovation partnerships such as this are driven by a desire to make a real-world sustainability impact. Bio-based feedstocks are a key part of Solvay’s sustainability strategy, and we look forward to being a consumer of bio-ACN from Trillium’s first bio-based acrylonitrile plant.”

Related Content

-

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.