Louisiana graphene startup reports R&D partnership, test results

TMTP’s graphene is reported to improve the tensile strength of epoxy by more than 400%, produced via a scalable, low-energy process. The company is targeting applications in composites, plastics and 3D printing.

Source | TMTP

Nanotechnology startup (New Orleans, La., U.S.), which specializes in graphene and advanced materials research, announces research and collaboration milestones toward industrial-scale production of its graphene products.

The company has recently conducted research trials with the Mississippi Polymer Institute, comparing tensile and flexural testing of neat epoxy versus graphene-impregnated epoxy. “We’re seeing a more than 400% increase in tensile strength with a 1% loading of our graphene,” says Matt Kelly, co-founder and CEO of TMTP.

“The epoxy resin industry is such a large industry, including many uses in composites, and we’re excited at the scale that we can grow in that area,” adds Seann Robbins, president and CTO of TMTP. “Composites are where we’re putting a lot of our focus, because it’s an industry that leans into our strengths. We’ve figured out that we can use specific processes for functionalization of our graphene that will translate across multiple different sectors within composites, including epoxies and carbon fibers.”

The company has also recently entered into a cooperative research agreement with global conveyance solutions leader Intralox (Harahan, La., U.S.). Through this collaboration, the companies seek to enhance the durability, strength and wear resistance of plastic materials used in conveyor belts and components, leveraging TMTP’s expertise in graphene-based additives with Intralox’s experience in global manufacturing.

According to Kelly, the addition of graphene has resulted in a more than 50% increase in impact strength for Intralox’s plastic components.

“This partnership between Intralox and TMTP will help build our foundation for advanced materials here in Louisiana,” says Robbins. “We are both Louisiana homegrown companies, and we believe in the innovation that can and will come from this region. We could not be more excited to do this important work with a global industry leader also based right here in Southeast Louisiana.”

In future, TMTP is targeting the needs of a variety of additional applications, including as a barrier enhancement in a composite pressure vessel to prevent leakage or cracking, or to help strengthen and lightweight composite automotive components or aerospace interior parts. The company is also working with the Louisiana Additive Manufacturing Association (LAMA) on use of graphene to enhance polymers used in industrial 3D printing.

About TMTP Labs

TMTP Labs was co-founded in 2021 by Robbins, Kelly and Tim Rustine, an engineer who originated the idea of developing graphene in a novel, scalable, sustainable and affordable method. The patented process is a top-down method that exfoliates layers of carbon atoms from graphite by essentially attaching it to “grains” of ice. A solution including graphite is added to a vessel containing ice. An agitator mixes the graphite solution and ice into a slurry, separating out the layers of carbon atoms in the graphite down to about three-atom-thick layers. The water is then removed from the slurry and a graphene powder remains.

“Most graphene exfoliation processes include milling or explosions of some sort, and these do work well but they also damage the graphene,” Kelly explains. “This is a method that uses very little energy and equipment, and results in a higher quality graphene because the materials aren’t damaging the material.”

“Our process also does not oxide the graphene as many others do, which makes the powder easier to transport and deliver because you remove the explosive risk,” Robbins adds.

At its current laboratory location, the company produces graphene at the kilogram scale for research and testing with customers, with plans to scale up its production equipment to produce 20 metric tons per year. “The beauty of this process is that it fits in a small footprint, this machine will only require 500 square feet of space,” Kelly says.

“Our goal is to manufacture a plug-and-play, pour-in product,” he adds. The company is working on functionalizations that enable the powder to be easily dispersed into a variety of plastics and resins.

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

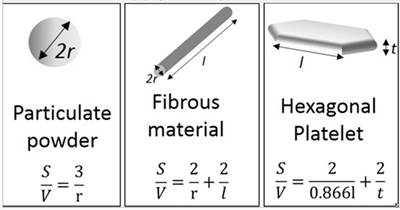

Nanomaterial types and definitions

Nanomaterials range in size, material, characteristics and usage in composites manufacturing. Provided here are types and definitions of those currently available.

Read MoreGraphene 101: Forms, properties and applications

Graphene-enhanced composites find new applications across end markets as the supply chain continues to mature.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More.jpg;width=70;height=70;mode=crop)