Hexcel signs long-term manufacturing contract with Boeing

Hexcel will produce HexPEKK-100 manufactured-to-print aerospace structures, including various air flow ducting applications and other supporting elements, for the Boeing 777X.

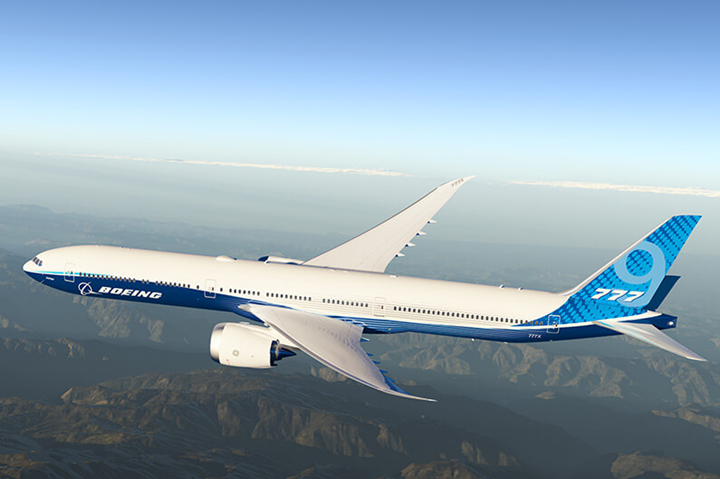

Photo Credit: Boeing

Hexcel Corp (Stamford, Conn., U.S.) has been awarded a multi-year contract to produce aerospace structures made with for the (Chicago, Ill., U.S.) 777X. The parts will be manufactured at the company’s additive manufacturing site near Hartford, Conn., U.S.

According to Hexcel, HexPEKK components can be manufactured-to-print for commercial aerospace, defense and space applications where complexity, lightweight and strong mechanical performance are critical. These 3D-printed parts reportedly meet interior aircraft smoke and toxicity requirements. HexPEKK end-use components — as well as the company’s HexAM additive manufacturing process — were added to Boeing’s Qualified Provider List (QPL) in 2019.

“We are pleased that Boeing has selected our additive manufacturing technology for these parts, and we appreciate their confidence in HexPEKK solutions for commercial aerospace applications,” says Colleen Pritchett, Hexcel’s president of aerospace, Americas and fibers.

HexPEKK parts selected by Boeing for the 777X family include various air flow ducting applications, as well as other supporting elements on the aircraft. Production of these parts is expected to begin later this year.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.