GKN Aerospace thermoplastic composites featured on Bell V-280 Valor

The thermoplastic composite components will be used for a demonstrator of the military V-tail aircraft.

Source | Bell Helicopter

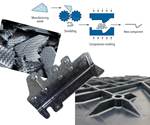

GKN Aerospace (St. Louis, Mo., U.S.) has delivered a pair of thermoplastic composite (TPC), induction-welded ruddervators, and two compression-molded access panels manufactured from reused thermoplastic waste material, to Bell Helicopter (Ft. Worth, Texas, U.S.) for a demonstrator of the V-280 Valor military aircraft.

GKN Aerospace has designed and manufactured the complete thermoset composite V-Tail currently used on the Bell V-280 Valor. The new thermoplastic ruddervators — which are control surfaces for the V-tail aircraft — and access panels are technology demonstrators planned for flight testing on the aircraft this year. This will make the V-280 one of the first military aircraft flying with thermoplastic components, the company says.

“It is very exciting that our cutting-edge thermoplastic technology will be flight tested for the first time on the state-of-the-art V-280 Valor,” says John Pritchard, CEO of GKN Aerospace ASEA.

The two compression-molded access panels have been manufactured from recycled thermoplastic waste material from the two ruddervators and have been developed in a Dutch TPC-cycle research program led by Saxion University (Enschede, Netherlands). GKN Aerospace is a partner in the research program.

Use of thermoplastic composite technology on a military platform will reportedly open up opportunities for wider applications in the defense market, offering advantages in terms of weight, costs, production time and environmental impact.

In addition to the demonstrator program, the GKN Aerospace global design team says it will support Bell with further design optimization of the V-Tail.

Related Content

-

Syensqo composites demonstrate titanium replacement on Boeing MQ-25 Stingray

Validation of integrating Cycom 5250-4HT prepreg into the UAV’s exhaust nozzle structure underpins the material system’s use in other high-temperature aerospace applications.

-

What you might have missed at Paris Air Show 2025

A surge in defense spending, partnerships in hydrogen propulsion and new combat aircraft agreements, many backed by composites industry leaders, culminated the 55th Paris Air Show.

-

FibreCoat develops radar-absorbing fiber-reinforced composite

Broadband, flexible material offers protection against radiation, heat and electromagnetic interference, and maintains performance across curved surfaces and slanted angles, outperforming existing materials by up to 100 times.

.jpg;width=70;height=70;mode=crop)