Fujitsu, Teijin start joint trials to promote value of recycled carbon fiber

Three-month trials with German bicycle manufacturers will lead to new platform implementation to promote use of recycled materials, enable emissions tracing/management.

Photo Credit: Teijin Ltd.

On Jan. 19, (Tokyo, Japan) and Teijin Ltd. (Tokyo) announced the launch of a joint project running from January to March 2023 to enhance the environmental value of recycled resources in the production of bicycle frames. Joint trials will include (Schmiedefeld), a German manufacturer and distributor of carbon fiber-reinforced plastic (CFRP) bicycle frames, and bicycle manufacturer (Frankfurt, Germany).

As part the trials, Teijin and Fujitsu will leverage a blockchain-based commercial platform launched in July 2022 to promote the sustainable use of recycled fiber-reinforced plastic (FRP) materials, as well as trace and manage greenhouse gas (GHG) emissions within the bicycle industry.

By implementing a business model that maximizes the environmental value from recycled materials, Teijin and Fujitsu aim to contribute to the further development of the carbon fiber recycling market and the realization of a circular economy. Following the successful conclusion of the joint trials, Teijin and Fujitsu will promote the implementation of the new platform, with the aim of commercialization in fiscal 2023. The two parties will also further promote discussions and field trials with partner companies and organizations that support this initiative and will work to contribute to the realization of a circular economy by supporting the growth of the recycling market in various industries.

Future visions and goals include:

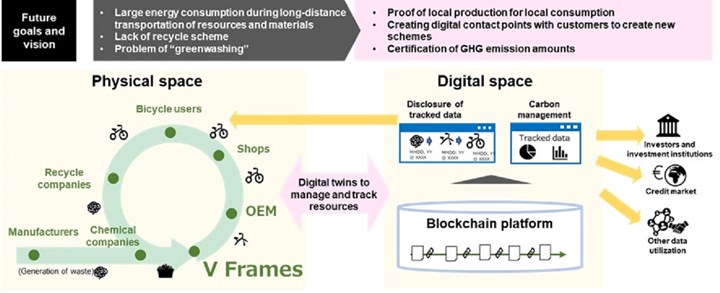

- The creation of “digital twins” to manage resources: Information about resources (their location, condition, environmental impact, etc.) used/generated in the business operations from the recycling to sales process of bicycle frames will be uploaded and provided on the platform to create digital replications (digital twins) of physical resources and manage information on their condition. Using blockchain technology, the platform will also offer past data on the condition of resources.

- Disclosure and utilization of data: Data from the platform can be used to share information on resources (origin of resources, etc.) with bicycle users, or be used by various stakeholders in their carbon management; data on the platform can further be used as proof for the successful realization of a resource cycle and applied for future ESG investment evaluations or as credits.

Throughout this project Teijin will support the environmental assessment across the different processes and engagement of stakeholders; Fujitsu will implement the blockchain platform based on the Fujitsu Track and Trust digital ledger technology and development of tool for visualization and provision of tracked data; and V Frames and Advanced Bikes will upload environmental impact information for different operational processes within the company to the platform, as well as review the data collection and visualization process.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreRead Next

Teijin partners with European carbon management firms for accelerated GHG emissions reduction

Combined know-how and expertise will be used to calculate life cycle analysis (LCA) and GHG emissions for environmental impact reduction in Teijin’s FRPs and other product life cycles.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More