Anisoprint expands global presence, announces exclusive partnership with Systemcreate

Systemcreate is a technology provider that will now exclusively distribute Anisoprint’s continuous fiber coextrusion technology and Composer system in Japan.

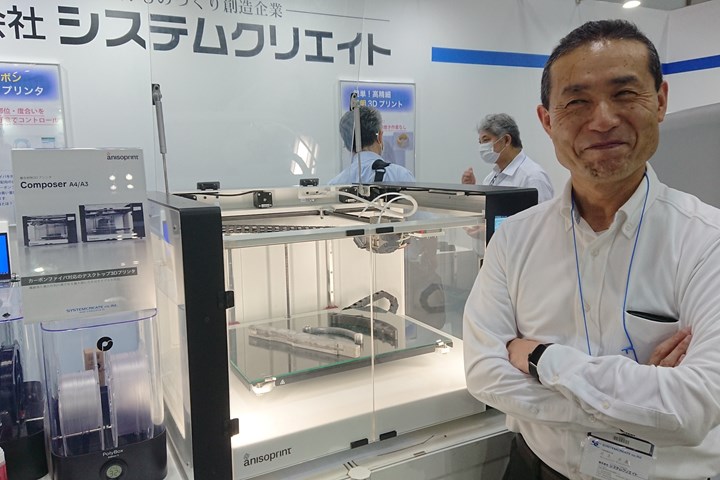

Masayoshi Kawakami, president of Systemcreate, at their booth at AM Japan, Tokyo, on June 23. Photo Credit: Anisoprint

Anisoprint (Esch-sur-Alzette, Luxembourg), a manufacturer of continuous fiber 3D printing systems, and (Tokyo, Japan) have announced an exclusive distribution partnership that will accelerate the adoption of 3D-printed continuous fiber-reinforced composites in the Japanese market. As part of the deal, Systemcreate will exclusively distribute Anisoprint’s proprietary continuous fiber coextrusion (CFC) technology and the .

As seen in the recent deals in China, and now Japan, exclusive distributor agreements have become Anisoprint’s main method for establishing stable and strong business relationships that encourages dedicated and committed work.

“Exclusive agreements are a cornerstone to building trust, close business relationships, and high productivity,” Takafumi Sakamoto, director of Asia and Pacific at Anisoprint, says. “We value the efforts and commitment that Systemcreate offers us and are eager to start working with such a strong and experienced partner.”

Systemcreate plans to invest more resources in marketing to promote the Composer systems, establish a team of engineers with in-depth understanding of the CFC 3D printing technology and provide outstanding customer support service.

“I am convinced that signing an exclusive distribution agreement for Anisoprint Composers will lead to our further growth,” Masayoshi Kawakami, president at Systemcreate, contends. “It is also my great pleasure that we can contribute and help Japanese engineers develop innovative products by using continuous carbon fiber 3D printers. We will now start collaborating closely with Anisoprint to accelerate cultivating the Japanese market.”

Anisoprint has also recently entered the .

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.