AMRC, industrial partners develop Type IV hydrogen tank for long-haul vehicles

In the 12-month project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has built prototype tanks and worked to build a secure U.K. supply chain.

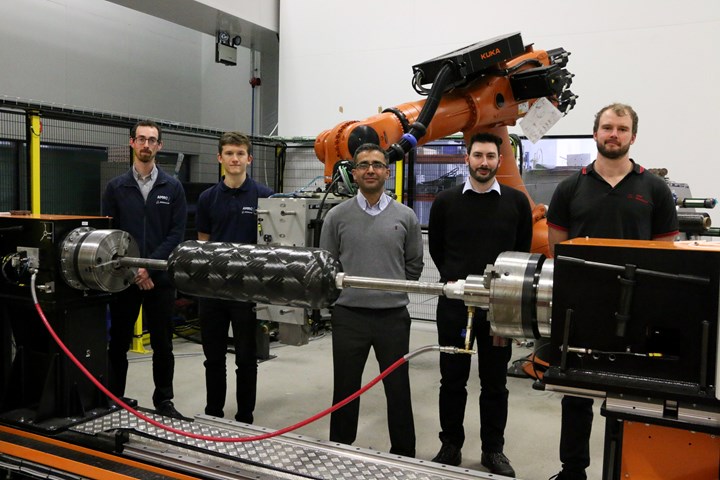

Composites experts from the (AMRC, Catcliffe, U.K.) have announced the development of a composite hydrogen storage tank for use in the heavy transport sector, with the goal of helping decarbonization of road transport.

In a 12-month project, the AMRC worked with (Bury, U.K.), a specialist in tooling design for rotationally molded parts, and (Eaton Socon, U.K.), which provides rotational, extrusion and compression molds for the automotive sector.

Together, they designed, manufactured and tested a Type IV cylindrical hydrogen pressure vessel, made from filament-wound carbon fiber over a thermoplastic liner. The tank has been designed for use in the automotive sector and has the capacity to hold 40 liters of hydrogen at a 350-bar pressure, with the testing being performed in line with EU regulations.

The next steps are to continue optimizing the designs and the manufacturing process of the pressure vessels, develop testing capabilities further and to increase storage capacity.

The AMRC, part of the national network of High Value Manufacturing (HVM) Catapult research centers, is at the forefront of hydrogen tank prototyping, says Zeeshan Qureshi, lead research engineer at the AMRC Composite Centre.

He says, “Using state-of-the-art machines, cost-effective processes and working closely with our two chosen SMEs, we are on a mission to help accelerate the U.K. hydrogen storage supply chain and enable rapid production of hydrogen pressure vessels through automated design, manufacture and validation to meet net zero targets and to help push forward the decarbonization of road transportation nationwide. The project has also given us the chance to manufacture hydrogen pressure vessels using a filament winding machine, a process that has not been explored much within the U.K. It has been a fantastic opportunity to be part of such a project and we’re excited to push our research and testing further in the next project we have lined up.”

Stuart Dawson, chief engineer for hydrogen at the AMRC, says, “Heavy long-haul vehicles [HGVs] are one of the most challenging segments of the road transport sector to reduce emissions due to their long journey distances and heavy payload requirements. For the operational economics to stack up, HGVs need long range and fast refueling. The high weight of batteries would reduce the vehicle’s potential payload & range and would require long recharging times. So for heavy duty, long range transport applications, hydrogen fueled vehicles — whether they are powered via fuel cells or combustion — are the ideal solution. Conventional metallic hydrogen storage tanks are heavy and would reduce the vehicle's payload. What is needed for transport applications is safe, affordable and lightweight hydrogen storage tanks.

Dawson adds, “However, despite the high projected future demand for such tanks, there is virtually no U.K. manufacturing capability for composite pressure vessels. This project seeks to address this issue through the development of globally competitive methods of manufacture for lightweight, Type IV hydrogen storage tanks that could eventually be deployed into U.K. industry.”

As a direct result of the AMRC struggling to find suitable suppliers, the collaborative project says it has successfully created a secure U.K. supply chain for thermoplastic liners for the country’s OEMs.

Steve Davies, managing director of Crossfield Excalibur, says, “This project has given us the chance to deploy our experience in rotomolding product design and toolmaking over a span of 25 years. Along with the wider team, we have designed and developed a rotomolding insert, capable of molding and using a high flow polyamide polymer which withstands significant pressures. We have thoroughly enjoyed working with both teams at the AMRC and Elite to bring this project to life and look forward to assisting with the next phase of development.”

Kris Heard, managing director for Elite GSS, adds, “Not only are we pleased to be developing a new and innovative product for the U.K. market, but we’re also testing and stretching our manufacturing abilities further than ever before. As a project it also fits in with some of our key objectives; as a business, we strive to manufacture and distribute new and revolutionary technology whilst also having a key focus on the environment and reducing our carbon footprint.”

Investment into the creation of these pressure vessels follows the launch of the government’s net zero and hydrogen strategies and is aimed at supporting the U.K. to reach net zero emissions by 2050. The project was funded by the HVM Catapult.

Related Content

OVERLEAF tackles thermoplastics, open cell insulation, sensors and testing for LH2 tank

Newsletter #4 gives latest status on EU project’s work toward thermoplastic composite tanks with 40% storage density of cryogenic hydrogen for future zero emissions aircraft.

Read MoreAirbus outlines next-gen single-aisle aircraft technology focuses, revised ZEROe project roadmap

Outlined technology bricks — including foldable wings, more efficient engines and propulsion and composite materials — could support a planned single-aisle next decade, plus Airbus’s renewed commitment of a commercially viable H2 aircraft.

Read MoreNew GTL breakthrough in composite tubing for liquid hydrogen in aircraft and space vehicles

Tests versus stainless steel tubing show 10 times faster chill down, fuel flow in 2 seconds and less boil-off for significantly faster fueling and refueling of LH2-powered space vehicles, aircraft and trucks.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More.jpg;width=70;height=70;mode=crop)