ACoSaLUS project updates for automated sandwich panel layup

Cevotec and project partners have made significant progress in line with 2023 completion, including improvement of automated handling, patch vision inspection, and the laminate design and patch placement process.

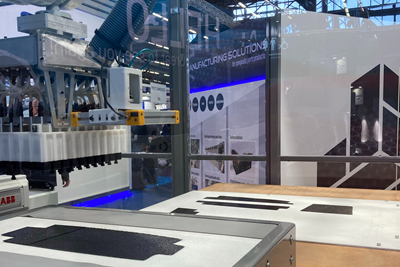

Patent-pending integrated gripper to precisely pick and place the honeycomb core. Photo Credit, all images: Cevotec

In 2021, together with German-based GKN Aerospace Deutschland GmbH (München), TUM – Chair of Carbon Composites (Garching), SGL Carbon (Wiesbaden), Augsburg University of Applied Sciences and Vabatec GmbH (München), Cevotec (Munich) launched the grant-supported project ACoSaLUS (Automated Composite Sandwich Lay-Up System). True to its name, the aim of the project is to automate the production of composite sandwich parts by developing and testing new manufacturing and control components and processes (learn more about the project). One of the project goals is to significantly improve the net layup speed for honeycomb sandwich structures by further advancing Cevotec’s fiber patch placement (FPP) technology. The company’s scope of work encompasses both software and hardware developments.

Cevotec reports further progress made over the past months since the project’s start. Cevotec has focused on the improvement of the laminate design and patch placement process as well as the robot-based, automated handling of honeycomb cores. Additionally, the optical post-placement control of patches using AI has been further improved.

In order to implement an end-to-end automated layup process, Cevotec has further developed its general FPP technology during this joint project and successfully placed the first skin patches directly onto the strongly curved tool (see video below). The placement features the company’s Rolling Motion movement applied to a six-axis robot, which uses it to precisely place patches on highly complex, convex-shaped surfaces. The movement of the placement robot is said to follow a curve with a different normal for each point of the curve. To support this accurate placement, Cevotec’s patch gripper has been improved as well, and now features enhanced vacuum and blow off controls. Currently, the company is optimizing placement parameters in preparation for the final demonstrator production.

Another improvement can be found in Cevotec’s patch vision inspection, with the development of a post-placement control using AI-based image recognition to match the strict manufacturing specifications and quality requirements needed by aerospace customers. After teaching the AI’s neural network, the system can detect edges and map different materials correctly. This enables the vision inspection to identify a successful placement. It also has the potential to be further upgraded to detect foreign object damage (FOD) and other defects. As illustrated in the picture below, the system can differentiate between various materials, such as honeycomb (including “hard points” for assembly), unidirectional (UD) and fabric patches. The new functionality of the vision inspection will be also tested in the production process of the final demonstrator.

Cevotec vision inspection AI.

Aside advancing the layup process, Cevotec notes that it is targeting a flexible manufacturing process to precisely place honeycomb material on complex geometries, increase the productivity and reduce overall cycle time. This includes development of a dedicated, patent-pending honeycomb gripper (seen in opening image) and an aim to implement an active force-feedback function to optimize compaction pressure during the layup process.

After successful tests, Cevotec has now integrated the honeycomb gripper prototype into its SAMBA production system, enabling an automated placement of complex-shaped sandwich cores on the mold with its six-axis robot (see video below). According to the company, the additional process step, now automated with FPP technology, represents a major achievement, since honeycomb placement could not be automated until now. A critical, manual process in the production of composite sandwich parts can thus be eliminated, increasing reproducible quality and production economics.

The ACoSaLUS project has entered its final phases of execution with completion until year’s end. The demonstrator produced as part of this project will be showcased at upcoming trade shows in the second half of 2023.

Related Content

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and Sicomin plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreAirbus to design, build ESA ExoMars rover lander platform

The resurrected Rosalind Franklin composite rover mission’s key systems will be upgraded with support from the TAS, ESA and NASA for a planned launch in 2028.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreAirbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

Read MoreRead Next

Techni-Modul Engineering grows automated technologies for composite part manufacture

New processes and approaches for kitting, stack and layup continue to be in high demand for composite industry OEMs, which TME backs with its SMART Control technology.

Read MoreUltra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More