CW Blog

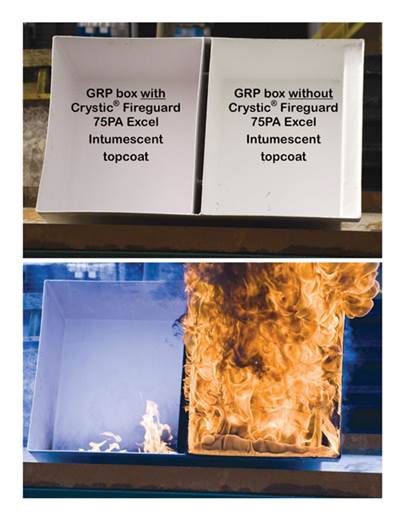

Improved intumescent: Topcoat allows better laminate performance

Applied to a cured laminate surface, a new intumescent topcoat provides Wright Composites (Galgorm, Ballymena, Northern Ireland) a passive fire barrier that permits the use of a laminating resin with less fire-resistant filler, making possible a tougher part.

Read MoreCorrosion resistance: Desert-bound chemical and potable-water tanks

RL Industries (Fairfield, Ohio) recently overcame logistical obstacles to successfully fabricate five large composite storage tanks for a chemical plant in Saudi Arabia.

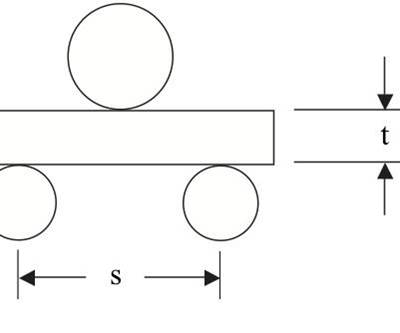

Read MoreThe short beam shear test

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses short beam shear testing methodology.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

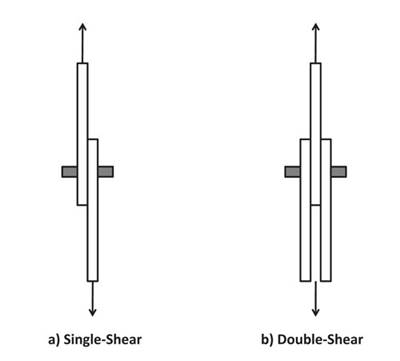

Read MoreFastener shear test methods

Dr. Donald Adams (Wyoming Test Fixtures, Salt Lake City, Utah) appraises existing methods for testing the performance of fasteners loaded in transverse shear.

Read MoreFacing the military drawdown

HPC editor-in-chief Jeff Sloan comments on the impact that military drawdowns in the Middle East might have on the U.S. composites industry.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

Read MoreFarnborough International Airshow 2010

Although uncertainties remain, aircraft OEMs see recovery in order numbers.

Read MoreEAA AirVenture 2010

Rain on the Wittman Field runways can’t dampen Oshkosh Fly-In enthusiasm.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreSPE's ACCE 2010 preview

Charting a composites course through the auto industry’s “perfect storm.”

Read MoreInterior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

Read More