CW Blog

Thermoplastic composites feel the love at NPE2015

At NPE2015, some of the key players involved in thermoplastic composites exhibited a variety of solutions that are leading growth in new and emerging markets.

Read MoreSlideshow of JEC Europe 2015

Another JEC Europe show (March 10-12) has come and gone and CW was there every step of the way reporting on the largest trade show for the industry.

Read MoreKnown knowns, known unknowns, unknown unknowns

JEC Europe 2015, March 10-12 in Paris, shed some light on where composites are, and where they're headed.

Read MoreMaking carbon fiber green

Composite Recycling Technology Center is being established in Washington State.

Read MoreCobham Composites: San Diego, CA, US

An aerocomposites force since the dawn of the 1980s, this fabricator’s Big Idea is to move from quality control to in-situ process control on the strength of metrics powered by Big Data.

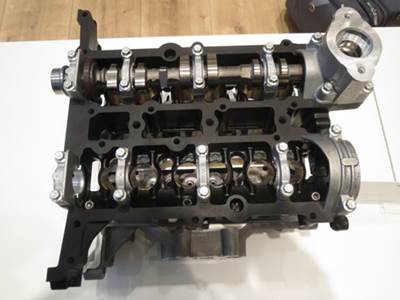

Read MoreAutocomposites Update: Engine oil pans

As thermoplastic composites makes inroads into these complex, modular parts, weight and cost go down, functionality goes up.

Read MoreYachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

Read MoreIntegrating NDI into manufacturing: Online inspection of CFRP prior to cure

Esmeralda Cuevas, head of NDT technologies at Tecnatom SA (San Sebastian de Los Reyes, Spain), details efforts of the TARGET project, which investigated how to integrate NDI into the composites manufacturing process prior to cure stage.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreModular composite tank kits

This fluid-storage tank component supplier employs Europe’s largest reusable vacuum bag

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreComposite manhole covers

UK utility trials ultralight access covers to reduce worker injuries and resulting compensation claims

Read More