CW Blog

GKN leads “STeM” program to successful conclusion

Technical achievements are credited to successful partner collaboration.

Read MoreGardner Business Index at 43.4 in January

Mid-sized U.S. production facilities expand; capital spending plans reach second highest level since August 2015.

Read MoreLaminated composites: The original additive manufacturing process

Because fabrication of laminated composites can claim to be the original additive manufacturing process, Altair Engineering Inc.'s (Troy, MI, US.) VP of aerospace solutions Robert Yancey says it also should be the most advanced in terms of application.

Read MoreIACMI – One insider’s perspective

A CW columnist, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (Knoxville, TN, US), Dale Brosius asks, “What if we took a ‘big hat’ approach to reach faster, more cost-effective solutions?”

Read More“Give us affordable carbon fiber!”

Guest columnist Dan Pichler, managing director of CarbConsult GmbH, suggests that the we need a sustained, cooperative effort in the carbon fiber supply chain. Partnering is the key.

Read MoreCan basalt fiber bridge the gap between glass and carbon?

When I started writing about composites in the way, way back, industry innovator Brandt Goldsworthy was still alive. His article on basalt fiber was one of the most-read columns in the old Composites Technology book, and there seems to be a lot of interest in this alternative performance fiber. Mafic SA is a new player in the basalt fiber market.

Read MoreCarbures: Conquering the world for composites

This global Tier 2 supplier produced 39,322 parts for Airbus in 2015, has sold seven RMCP machines to China capable of 40,000-75,000 composite auto parts/yr and is completing a study on opportunities for composites in oil and gas applications in Mexico. What next?

WatchLEAP backlog spurs composites production expansion

If some were unaware of the significance CFM International’s composites-intensive LEAP engine, there was no ignoring two announcements in February that signaled just how massive this commercial jet engine program is and will be.

Read MoreVBO prepreg on wing structure

GE Aviation scores first use of OOA wing trailing edge on large commercial aircraft.

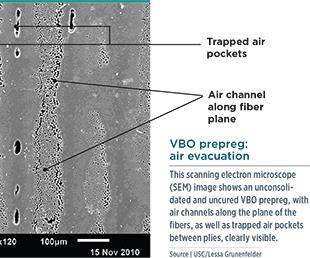

Read MoreResearch on OOA processing continues

Much work has been done to make OOA processing practical for aerospace applications, but much work still remains if it is to become the compelling option.

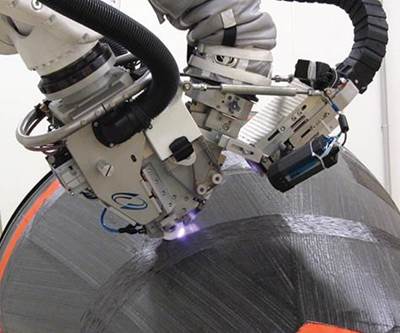

Read MoreDry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

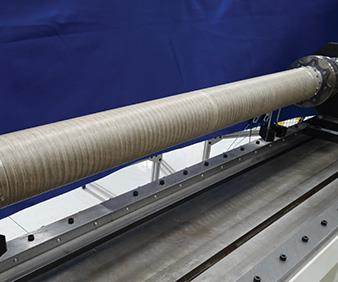

Read MoreOOA: Thermoplastic alternative targets performance spec

CF/PEEK helicopter driveshaft’s toughness trumps traditional metric.

Read More