Torque-multiplication: A Euro 7-ready diesel supercar?

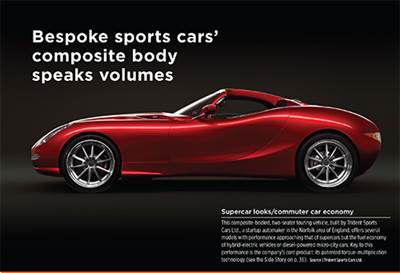

The all-composite body on Trident Sports Cars Ltd.'s Iceni sports car is the attractive package designed to showcase the centerpiece of the company's drivetrain, it's design team’s unique torque-multiplication technology, for which the company holds 64 patents.

At Trident Sports Cars Ltd., the signature feature of the Iceni sports car drivetrain is the team’s unique torque-multiplication technology, for which the company holds 64 patents. When it’s harnessed with a modified 6.6L turbo-charged direct-injected V8 Duramax diesel engine from General Motors Co. (GM, Detroit, MI, US), and Trident’s own six-speed automatic or manual transmissions, the Iceni models powered by the combination are fully compliant with Euro 6 diesel emissions legislation that phases in this year. In fact, Trident’s powerplant surpassed Euro 6 requirements in 2008, and in 2012 it surpassed Euro 7 emissions mandates, which won’t become law until 2020.

Duramax engines typically power GM full-size pickups and commercial vans — vehicles known for power/torque, not speed. Nevertheless, the above combination enables the base Iceni to accelerate 0-97 kmh in 3.7 seconds and top out at 306 kmh, putting it in supercar territory. The base vehicle produces 397 hp and 700 lb/ft of torque, but engine upgrades can boost that to 430 and 660 hp, producing 950 and 1,050 lb/ft — more than three times the torque of a typical high-end sports car or supercar — and accelerating 0-97 kmh in 3.2 and 2.9 seconds, respectively.

“Just as everyone thinks there’s no substitute for cubic inches in the engine,” explains Trident’s Phil Bevan, “they also obsess over crankshaft horsepower. What they fail to realize is that if you’re running a car at 8,000-9,000 rpm, you’re going through fuel at a rapid clip. We’ve taken a different approach and change gears at 3,000 rpm. By cutting engine revs by more than 50%, we also halve fuel use and emissions. People overlook the value of torque.” But Bevan observes that the low horsepower/high torque that defines Trident vehicles can be both blessing and curse because it yields a … different driving experience. No potential customer of a Trident Iceni can buy a car without a test drive or two.

Another unique aspect of all Trident’s vehicles is that they feature multi-fuel engines that will run on any oil-based fuel, from conventional diesels or bio-diesel to mineral oil, paraffin, kerosene and central-heating oil. When fueled by annually renewable, carbon-fixing, plant-based bio-diesel (e.g., from new or used cooking oil), the vehicles offer another unique benefit: Plants from which cooking oils are derived absorb carbon and nitrogen (greenhouse gases) during their growing cycle. When they are harvested, and ultimately used to make a bio-fuel, they represent a credit — a net carbon offset. When bio-diesel is burned in the Trident vehicle, the owner, in theory, cashes in on the carbon credit from the plant’s work during its lifecycle, especially if the fuel is made from used cooking oil. Then the vehicle technically operates at a zero (net) carbon footprint.

Onboard diagnostics and computer-controlled systems will sense fuel changes from tank to tank and automatically adjust various combustion conditions and other ratios to maximize efficiency. To reduce emissions further, a new feature, hydrogen injection, will kick in and burn any unburned fuel and particulates when the engine isn’t operating at maximum efficiency.

This short article is a sidebar to a feature article titled "Bespoke sports cars' body speaks volumes" and a companion sidebar titled "Chassis: Unique achitecture and materials" To read either article, click on its title under "Editor's Picks," at top right.

Related Content

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreRead Next

Bespoke sports cars’ composite body speaks volumes

Glass-reinforced plastic artfully captures classic curves, crash-protects passengers and stunningly packages its maker’s high-performance but highly fuel-efficient diesel powertrain.

Read MoreChassis: Unique architecture and materials

Trident Sports Cars Ltd.’s Iceni chassis is formed from 4003 low-chrome/low-carbon stainless steel. It isn’t pretty, but it won’t rust and more importantly, it’s very resilient , making it perfect, says the company, for chassis construction

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More.jpg;width=70;height=70;mode=crop)