Articles

Fighting Ships Augment Combat Readiness With Advanced Composites

Navies adopt composite materials for stealth and speed.

Read MoreMetal Matrix Composites Advance Optoelectronics Package Design

Cast aluminum silicon carbide keeps costs down while providing ideal thermal properties.

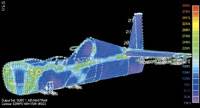

Read MoreDesigning The Chanute Aerobatic Aircraft

Finite element modeling speeds development time and reduces uncertainty.

Read MoreAirbus A340 carbon composite spoiler made with RTM

When FACC AG (Ried, Austria) contracted to fabricate a demonstration composite replacement part for a highly stressed aluminum spoiler center fitting on the Airbus A340-600, the company wanted to use resin transfer molding (RTM) because the part's complex shape would be difficult to produce consistently and

Read MoreAdvanced Pultrusion Takes Off In Commercial Aircraft Structures

Innovative prepreg pultrusion process forms profiles equal to autoclaved components at lower cost.

Read MoreStructural S-Glass laminates for V-bottomed offshore powerboats

Winning powerboat manufacturer specifies VeTron S-2 glass.

Read MoreFREEDOMCar Program to Develop Future Composite Car

Automotive technology aimed primarily at increasing the fuel efficiency of propulsion systems and/or developing alternative fuels that would reduce emissions has been a concern of the U.S.

Read MoreFiberglass architectural elements restore Ferry Building

In a city filled with memorable landmarks, perhaps the most enduring is San Francisco's Ferry Building. A recent $90 million refurbishment included fiberglass architectural elements fabricated by Kreysler & Assoc. (American Canyon, Calif., U.S.A.) Completed in 1898 as the passenger terminus for the bay's ferry

Read MoreCarbon Composites for Sports Cars and Mass Market Cars

A confluence of market demand, new product development and competition among automakers fuels growth in use of carbon fiber composites.

Read MoreVinyl Esters Make Tough Parts For Highly Corrosive Applications

An array of case studies showcases the growing acceptance of fiberglass/vinyl ester composites in harsh industrial environments.

Read MoreSAMPE Wrap Up And Product Showcase

Exhibitions on both sides of the Atlantic spur optimism and spotlight innovative technology.

Read MoreIsotruss offers amazing strength and material savings

The three-dimensional composite truss structure is the lightest and most efficient structural tube available.

Read More