Composites-focused engineering, simulation services company launches in Germany

Simutence GmbH, a company started by Karlsruhe Institute of Technology graduates, offers custom simulation methods to composites manufacturers across end markets.

Three recent graduates of Karlsruhe Institute of Technology (KIT, Karlsruhe, Germany) have launched a “virtual composites solutions” company called Simutence GmbH (also in Karlsruhe) to offer design and engineering services, including custom simulation methods that plug into popular simulation tools. Customers in the automotive, aerospace and sporting goods/recreational fields are the primary targets.

Simutence GmbH (Karlsruhe, Germany), a “virtual composites solutions” company, is now offering design and engineering services, including custom simulation methods that plug into popular simulation tools. The owners have worked on a number of public and private composites-intensive programs, so are well experienced in converting metal designs to composites using a wide range of thermoset and thermoplastic materials and processes. Source | Simutence GmbH

The company was co-founded by Dr.-Ing. Martin Hohberg (who specializes in filling simulation for discontinuous-fiber-reinforced thermoplastics and thermosets, particularly locally reinforced, compression-molded sheet molding compound); Dr.-Ing. Benedikt Fengler (who specializes in topology and layup optimization, and leads group efforts in the use of locally continuous reinforcement in otherwise discontinuous fiber composites); and Dominik Dörr (a doctoral candidate with a specialization in draping simulation, especially unidirectional thermoplastic tapes, and who leads group efforts in continuous fiber composites). The trio met during their doctoral studies at KIT, where they also participated in a consortium focusing on transportation lightweighting solutions, including composites. Additionally, they worked on Project SMiLE (System integrative Multi-material Lightweight construction for Electromobility) sponsored by the German government (see “Hybrid thermoplastics give load floor impact strength”).

Virtual process chain

The team provides engineering consulting and simulation work, develops and supplies custom-made plug-in/add-on simulation tools, and offers training — including how to convert metal designs to composites and how to select and optimize material and process technologies — for a wide variety of thermoset and thermoplastic composites as well as hybrid metallic/composite structures. For customers without in-house engineering support or without engineers familiar with composites, Simutence can provide full design engineering services as well as training. And for customers struggling with thorny engineering issues, the team has developed a series of its own software plug-in/add-on tools for customers that work in popular multipurpose finite element analysis (FEA) codes like Abaqus (from Dassault Systèmes, Vélizy-Villacoublay, France) and process simulation codes like Moldflow (from Autodesk Inc., San Rafael, Calif., U.S.). Where those standard tools don’t work or where a customer needs a different type of engineering solution, the team also develops custom tools to meet specific requirements.

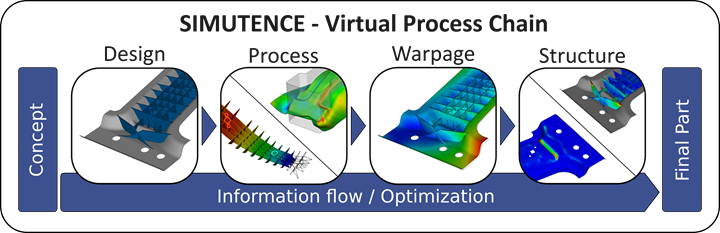

“Our mission is to help designers and manufacturers of composite parts develop and optimize lightweight parts and processes by our virtual process chain,” explains Fengler. Developed at KIT and “industrialized” (commercialized) by the team, the virtual process chain is the product development approach taken by Simutence on customer projects and is supplied (as plug-in/add-on tools) to customers for in-house engineering projects. It begins by defining engineering goals and then developing a materials-specific design to meet all functional requirements. Next, process simulation is applied to assure manufacturability, select suitable processing parameters and predict conventional manufacturing effects (for example, forming-or filling-induced fiber orientation) as well as defects (for example, wrinkling, dry spots, filling issues, etc.).

“Our advanced modeling techniques for process and structural simulation as well as the interfaces we’ve built to allow for the continuous transfer of manufacturing effects to subsequent simulation steps enables us to enhance the modeling capabilities of commercial software architectures,” notes Hohberg. “In turn, this means we can significantly increase predictive accuracy and provide our customers with simulation results faster.”

Since dimensional accuracy can be a critical issue with composite designs, the team next applies warpage and thermomechanical analyses (including curing/crystallization kinetics) to predict dimensional changes and to evaluate residual stresses. The last step is to conduct structural analyses, in order to assure the design fulfills load requirements, determine stiffness and provide damage initiation and initial failure modes analysis.

Process simulation expertise

“The structural behavior of fiber-reinforced composites is distinctly influenced by manufacturing effects,” adds Dörr. “By applying our virtual process chain, we are able to consider manufacturing effects on structural performance. These virtual design loops help to reduce development time and resources by eliminating many rounds of design and physical part testing owing to their accuracy and reliability. Since we operate in a neutral exchange format, we can link to a variety of different software packages our customers are currently using.”

Reportedly, the team already is hard at work readying the first release of plug-ins/add-ons for thermoforming simulation, filling simulation of compression-molded sheet molding compound (SMC), and interfaces for mapping and homogenization — all of which will be available for the Abaqus FEA suite. Beyond that, the partners are engaged in applying the entire virtual process chain to customer engineering projects.

“Lightweight construction necessitates clever use of materials, processes and design techniques,” continues Fengler. “Customers using holistic, interdisciplinary approaches to product development from a continuous CAE [computer-aided engineering] supply chain like Simutence benefit in terms of speed, reliability and cost. Our expertise in composites simulation and our background as a spinoff from Karlsruhe Institute of Technology enables us to support state-of-the-art simulation methods.”

Last May, Simutence was selected as one of six Hemholtz Enterprise funding recipients (from Hemholtz Association of German Research Institutes, Bonn and Berlin, Germany) and has secured startup funding for its first year. Initially, the team will be co-located at KIT, sharing office space and equipment with the university. Although an independent entity, when needed Simutence engineers will be able to draw upon R&D resources in the areas of process technology from Fraunhofer Institute for Chemical Technology (Pfinztal, Germany) and the University of Western Ontario (London, Ontario, Canada) and in materials characterization from the Institute for Applied Materials at KIT.

Related Content

Dieffenbacher acquires Schmidt & Heinzmann composites business

The acquisition, which includes all intangible assets of the business unit, will expand Dieffenbacher’s SMC delivery spectrum, enable potential for portfolio growth and synergies.

Read MoreComposite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreAOC resins support SMC composite doors for air raid shelters

The recent use case exemplifies the application of AOC’s SMC resins in related fields, thanks to their strength, resistance and longer lifespan in comparison to metal or fiber-reinforced concrete options.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreRead Next

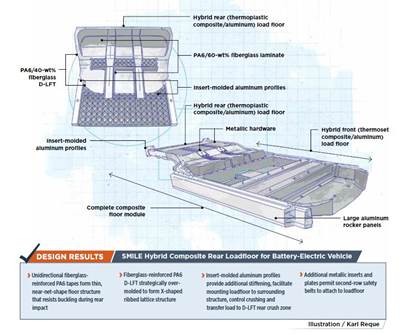

Hybrid thermoplastics give load floor impact strength

Project leads to development of new compression process for selective application of D-LFT on UD tape laminates.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More.jpg;width=70;height=70;mode=crop)