Composites enable innovative prototype for snow mountain bike

A group of engineering students from the University of Sherbrooke (Québec, Canada) believe mountain biking should be enjoyed year-round.

A group of engineering students from the University of Sherbrooke in Québec, Canada believe mountain biking should be enjoyed year-round. The students have developed a new bike concept that can be adapted to mountains downhill on the snow.

“This prototype will be unique in its capacity to reproduce the same feelings and behavior of a conventional mountain bike,” the group said.

The design is a dual-ski system for braking and handling. The user has to grip a regular brake lever to activate a small hydraulic cylinder to open up the skis so the bike brakes.

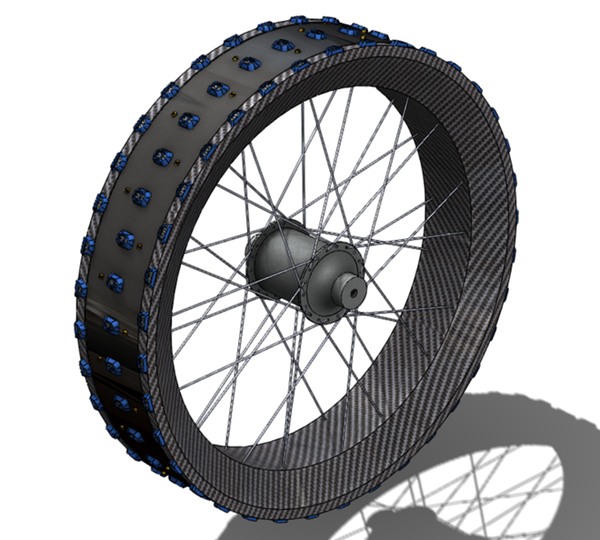

The propulsion system includes quite a few components. The students say they wanted to make it as light as possible, but it has to handle the impacts received while riding a downhill mountain bike. They created the principal rim with a blend of aluminum and carbon fiber. The whole system will be driven by an internal geared hub.

Principal rim

To judge the project’s success, the key components they will evaluate are stability, braking capacities, maneuverability and propulsion. All these criteria will be tested in various snow conditions and compared to the performances of a regular mountain bike used in the summer. The students claim that bikes currently on the market do not perform well in all these criteria, either by the absence of a propulsion system or by poor maneuverability.

As is typical with most college students—this group is working with limited funds. They have a few sponsors and the group has also launched a campaign to help raise more money.

The students hope to have this prototype ready by December 2015. They are “confident about delivering a functional prototype meeting all the requirements previously set to fulfill the lack of thrills suffered by the mountain bike lovers during the winter."

The group put together a nicely made video detailing the project. Check it out here:

Related Content

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.