Carbon fiber Hyperloop design to transform transportation

A group of Carnegie Mellon University students will test out their carbon fiber pod design during a competition at SpaceX’s headquarters in August.

Imagine the potential to travel from distances such as Los Angeles to San Francisco in 30 minutes. It’s not science fiction, it’s not a concept that won’t happen for another 50 years— it’s on track to be our new reality, thanks to Elon Musk and some of the brightest university students around the world. Back in 2013, Musk first unveiled the idea for a new high-speed ground transport system, named Hyperloop. It would feature a network of tubes that could span hundreds of miles. In order to accelerate the development of Hyperloop, Musk announced a competition that called on universities to compete and build the best Hyperloop pod.

For college students that want to make a difference in the world, it’s a dream project. This past January, Texas A&M University sponsored a Design Weekend where more than 100 teams competed to become semi-finalists in the Hyperloop Competition. One of the finalists from that competition includes a group of Carnegie Mellon University students whose design is “solid and impressive,” according to SpaceX. Carnegie Mellon Hyperloop is an interdisciplinary team of more than 50 engineers, designers and business students with the vision of taking the pod all the way through the competition to win.

The 30 different student teams, including the group from Carnegie Mellon, will have the chance to test out their pod designs on the one-mile test track outside of SpaceX’s headquarters in Hawthorne, Calif. in August.

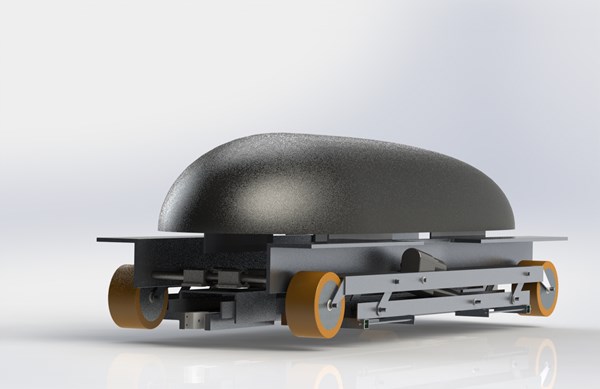

I talked with some of the students from Carnegie Mellon as their design includes a carbon fiber shell, which encloses the various components of the pod. The dimensions of the carbon fiber structure are 8 foot by 3.5 foot by 3 foot. Here's a photo of the design:

“Being a student team, this is the first time the team members are building a huge carbon fiber shell and a big challenge is to make the high-quality mold for the carbon fiber layup,” said Siddharth Alampally, graduate student of the Mechanical Engineering Department at Carnegie Mellon. “This is a process that needs patience with such a big structure.”

“We decided to build a carbon fiber-reinforced plastic structure because it has a very high strength-to-weight ratio and we chose the process of resin infusion as it allows us to manufacture a custom shape with high-quality,” he said.

Other components of the pod include maglev, magnetic levitation, which is not used in transportation anywhere in U.S. and bringing these concepts to reality is another big challenge.

“In our efforts to design a truly scalable Hyperloop pod, we find ourselves dealing with questions that even industry experts have trouble answering,” the students wrote on their Crowdfunding page. “The most pressing issue is that of the air bearings we intend to use. Even the most promising alternative for our levitation system, an air caster style bearing, has never been tested at the extreme conditions that have been proposed for the final event.”

The situation requires that they carry out primary research and prototyping by putting together a test rig that artificially simulates these conditions for the Levitation assembly. The group plans to complete the pod by the last week of July so that it gives more time for testing.

Wish the team luck for the August competition and go team carbon fiber!

Related Content

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More