Photo Credit: Candela

The Candela P-12 Shuttle is a hydrofoiling electric ferry set to hit the waters of Stockholm, Sweden, next year. Marine technology company (Stockholm) claims the ferry will be the world’s fastest, longest-range and most energy-efficient electric ship yet. The Candela P-12 Shuttle is expected to reduce emissions and slash commuting times, and will shuttle up to 30 passengers at a time between the suburb of Ekerö and the city center. With a speed of up to 30 knots and a range of up to 50 nautical miles per charge, the shuttle is expected to travel faster — and more energy efficiently — than the diesel-powered bus and subway lines currently servicing the city.

Candela says the key to the boat’s high speed and long range will be the ferry’s three carbon fiber/epoxy composite wings that extend from under the hull. These active hydrofoils enable the ship to lift itself above the water, decreasing drag.

The P-12 Shuttle features carbon fiber/epoxy wings, hull, deck, inner structures, foil struts and rudder built via resin infusion. The foil system that actuates the foils and holds them in place is made from sheet metal. According to Mikael Mahlberg, communications and PR manager at Candela, the decision to use carbon fiber for most of the boat’s main components was lightness — the overall result is a roughly 30% lighter boat compared to a glass fiber version. “[This weight reduction] means we can fly longer and with heavier loads, Mahlberg says.

The principles for designing and manufacturing the P-12 are similar to those of Candela’s composites-intensive, all-electric foiling speedboat, the C-7, including composite, aerospace-reminiscent stringers and ribs within the hull. On the P-12, this design is incorporated into a catamaran hull, which was used “in order to make a longer wing for added efficiency, and better efficiency at low displacement speeds,” Mahlberg explains.

As the hydrofoiling Candela P-12 Shuttle creates near zero wake, it has been granted an exemption from the 12-knot speed limit, enabling it to fly into the city center without causing wave damage to other vessels or sensitive shorelines. In fact, the propeller wash is considerably smaller than the wake from conventional passenger ships traveling at slow speeds, Candela says.

The boat is also said to provide an extremely steady, smooth ride, aided by both the foils and an advanced computer system that regulates the hydrofoils 100 times per second. “There’s no other ship that has this kind of active electronic stabilization. Flying aboard the P-12 Shuttle in rough seas will feel more like being on a modern express train than on a boat: It’s quiet, smooth and stable,” says Erik Eklund, vice president, commercial vessels at Candela.

The Region of Stockholm will operate the first P-12 Shuttle ship for a nine-month trial period during 2023. If it meets the high expectations placed on it, the hope is that the city’s fleet of more than 70 diesel vessels eventually will be replaced by P-12 Shuttles — but also that land transport from congested highways can shift to the waterways. In rush hour traffic, the ship is said to be faster than buses and cars on many routes. Thanks to the hydrofoil’s efficiency, it can compete on mileage costs too; and unlike new subway lines or highways, it can be inserted on new routes without massive infrastructure investments — all that is needed is a dock and electric power.

Candela’s vision is to replace today’s large, predominantly diesel, ships with nimble fleets of faster and smaller P-12 Shuttles, enabling more frequent departures and more passengers to be carried at a lower cost for the operator. On the Stockholm-Ekerö route, Candela’s proposal is to replace the current pair of 200-person diesel vessels with at least five P-12 Shuttles, which would double passenger volume potential and lower operating cost. Instead of two departures per day, there would be a P-12 Shuttle departing every 11 minutes. “This allows commuters to ignore timetables and just go to the dock and wait for the next boat,” says Eklund.

Candela plans to begin manufacture on the first P-12 Shuttle by the end of 2022 at its new, automated factory in Rotebro, outside Stockholm, coming online in August 2022. After initial tests, the ship is expected to embark with its first passengers in Stockholm in 2023.

Following the first successful build and launch, Candela aims to ramp up production at the Rotebro factory to hundreds of P-12 Shuttles per year, incorporating automation such as industrial robots and automatic cutting and trimming.

Related Content

Designing an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreRecycled carbon fiber composite panels power 40% lighter, durable semi-rigid solar panels

Designed for auxiliary power use while traveling via boat or RV, Italian startup Levante’s custom flexible or standardized semi-rigid solar panels combine the benefits of ReCarbon’s rCF and thermoplastics.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreRead Next

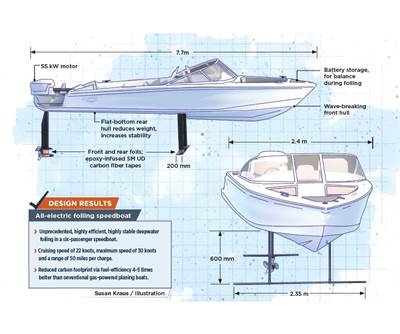

Composites enable novel flying speedboat

Candela Boats’ Seven speedboat combines all-electric propulsion with precision foiling in a design made possible by creative composites engineering.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More

.jpg;width=70;height=70;mode=crop)