Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

Share

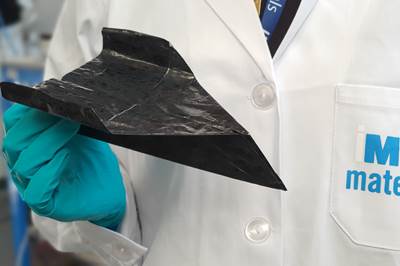

Source | Total Resin

(Naucalpan, Mexico) presents Total Nanotüp, a concentrated dispersion of carbon nanotubes (CNTs) contained in a high-performance bifunctional reactive monomer, recommended by the company for polyester, vinyl ester, melamine and acrylic resins.

Total Nanotüp dispersion is designed to provide optimal electrical conductivity to polyester resins (solvent-free and solvent-based), melamine (solvent-free and solvent-based) and acrylic systems while maintaining mechanical properties. It is a smooth paste dispersion, and is said to be efficiently mixable into resins.

Total Nanotüp is a single-walled CNT additive that provides electrical conductivity at low doses with minimal impact on rheological properties, which can grant customers the benefits and performance of CNTs. It is also said to minimize reformulations and accelerate product innovation.

Possible applications include:

- Antistatic property

- SMC/BMC processes, RTM, hand lamination, spray lamination and pultrusion processes

- Gelcoat coatings

- Resins for tooling

- Gelcoat tooling

- Antistatic tubes and tanks for fuels

- Electrostatic discharge materials applied by coil coating

- Other applications requiring electrical conductivity

According to the company, Total Nanotüp enables a dosage from 1 wt.%. It allows for simple dispersion and incorporation using common dilution equipment, and enables the production of conductive parts that retain intense colors. In addition to preserving and increasing mechanical strength, the dispersion technology achieves uniform and permanent electrical conductivity without “hot spots,” and optimizes surface quality, due to minimal dust attraction. There is no significant increase in material viscosity and density and demolding of parts is enhanced.

Depending on the characteristics of the polymer and processing conditions, the loading dose of Total Nanotüp dispersion for antistatic or dissipative applications can reach values of 1-13 wt.%. These calculations are made based on non-volatile material. The exact loading dose depends on the required performance, resin properties, processing conditions and the presence of other ingredients.

Related Content

-

Automated composites processing systems facilitate customization, productivity

CAMX 2025: Mikrosam’s filament winding, prepreg slitting and rewinding, towpreg, AFP/ATL and flexible double-belt press prepreg equipment meet precision and quality demands.

-

Autonomous agents optimize decision flows in aerospace, composites production

CAMX 2025: With manufacturers face labor shortages, increasing product complexity and pressure to operate sustainably, Plataine’s AI Agents provide the agility and intelligence needed for real-time decision-making.

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Related Content

Automated composites processing systems facilitate customization, productivity

CAMX 2025: Mikrosam’s filament winding, prepreg slitting and rewinding, towpreg, AFP/ATL and flexible double-belt press prepreg equipment meet precision and quality demands.

Read MoreAutonomous agents optimize decision flows in aerospace, composites production

CAMX 2025: With manufacturers face labor shortages, increasing product complexity and pressure to operate sustainably, Plataine’s AI Agents provide the agility and intelligence needed for real-time decision-making.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreRead Next

Mechnano, Bomar introduces E35B+ masterbatch with increased CNT concentration

Using Mechnano’s D’Func process, the new masterbatch of ogolimers enables 3D printing resin development with improved mechanical and nano-uniform electrical performance.

Read MoreIMDEA Materials demonstrates recyclability of CNT sheets

Researchers have proven it’s possible to recycle CNTs at the macroscopic scale with nearly 100% retention of mechanical and electrical properties, removing a hurdle to sustainable CNT-based fiber, sheet and textile adoption.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More