Composites 4.0

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

Siemens, Ducati extend partnership to advance innovation

Siemens Xcelerator Platform helps extend racing innovation to production bikes, reduces time for complex composite parts and enables remote design/3D printing at track, digital twin and faster development.

Read MoreAltair 2025 Enlighten Award winners, runner-ups push automotive boundaries

Hemp nylon-reinforced PA6 automotive exteriors, TPC acoustic elements, glass fiber stator cooling design and other innovations are recognized for their sustainability focus, holistic capabilities and lightweight designs.

Read MoreAltair, NIAR sign MOU to build aerospace innovation space

Collaboration will expand digital twin adoption, empower aerospace startups and speed up product development and certification processes.

Read MoreStack3D invests in, integrates CEAD Hybrid Flexbot

Stack3D pairs the LFAM FlexBot with its own R&D and materials processing capabilities to offer rapid, end-to-end production from prototyping to low-volume manufacturing.

Read MoreOtto Aerospace develops AI model for Phantom 3500 business jet aerodynamics

Tailored AI model will enable detailed aerodynamic analysis of current and future Otto aircraft configurations, streamlining design speed, precision and informing the aircraft program’s composite structures.

Read MoreHoly Technologies selects Plataine to scale up smart composites production

Plataine’s AI agents for scheduling and traceability will enable Holy Technologies to optimize serial production plans, reduce manual effort and build a scalable foundation for future growth.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Stewart Mitchell

Contributing Writer

Xitadel XIPA imparts more intelligent CAE simulation workflows

Automated preprocessing, FE model building and postprocessing are powered through machine learning and Gen AI tools, supporting enhanced speed, accuracy and efficiency.

Read MoreDaher ODDICEA 2 project gains support to boost decarbonization of TPC production activities

Renewed financial support from France’s Pays de la Loire region will build on technological Industry 4.0 advances made in the project’s first phase for Daher’s Nantes facility, which has already delivered tangible results.

Read MoreUniSQ, iLAuNCH Trailblazer program drive digital twin innovation for composite repairs

Working with Boeing Australia, Memko and Dassault Systèmes, the University of Southern Queensland (UniSQ) has developed a digital twin via the 3DEXPERIENCE platform, digitizing processes that could lead toward more efficient and effective maintenance, repair and operations of future fleets.

Read MoreHorizon Europe projects present webinar for advancing aviation digitalization, composite technologies

Free webinar on Sept. 24, 2025, brings together members from DEMOQUAS, GENEX and TOSCA to delve into how these projects are contributing to safer, more efficient and environmentally responsible aviation technologies.

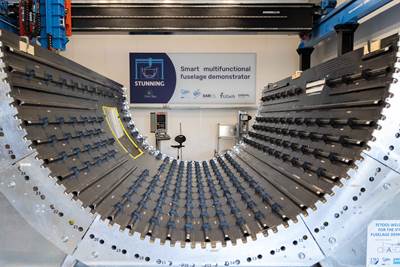

Read MoreSmart composites equipment advances aerocomposites innovation

CAMX 2025: From fiber to flight, Broetje-Automation innovates composites manufacturing with integrated AFP, drilling and sealing technologies.

Read MoreAnsys launches 2025 R2 with enhanced simulation, accessibility and AI

Ansys 2025 R2 amplifies human ingenuity with AI-driven tools and features that simplify simulation adoption, encourage collaboration and boost productivity across teams.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

Seoul National University VABS to design UAM, rotorcraft blades

University conducts research to establish conceptual and detailed design methodologies applicable to composite UAM systems and to develop digital twin technologies that can be used in aerospace.

Read MoreORGANIC project to 3D print bio-inspired structures with bio-based materials

EU-funded Horizon Europe project tackles lower production cost, enhanced sustainability and first-time-right parts fabrication through the fusion of biology, additive manufacturing and AI.

Read MoreLayup molds, vacuum fixtures address aerospace tooling trends

CAMX 2025: Technical Tooling is integrating advanced materials, digital process compatibilities and automation into its low-CTE Ravin layup molds and Vacu-Grip fixture offerings to meet evolving needs.

Read MoreContactless sensors enable smart composites production

CAMX 2025: Attendees can experience both of sensXPERT’s FlexCure and Insight sensor products, both achieving reduced waste, shorter cycle times and more actionable insights into resin curing.

Read MoreVericut CNC simulation software enhances machining precision with AI

Vericut (CGTech) introduces Vericut 9.6, featuring AI-driven tools and productivity enhancements for streamlined workflows and improved shop floor collaboration.

Read MoreAltair, DAC join efforts to increase digital maturity of aerospace suppliers

Enhanced access to digital tools will support SMEs and startups at all levels, fostering innovation and resiliency and reducing supply chain fragmentation across Italy and Europe.

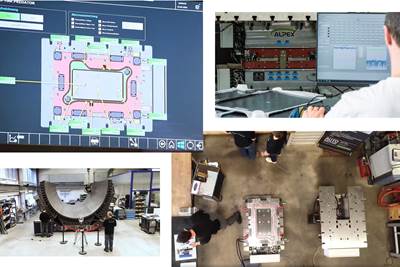

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

The Wallonia Composites Learning Network launches in Belgium

First session on Industry 4.0 was attended by 22 people representing 16 companies, future sessions planned on sensors, circularity and recycling of composites waste.

Read MoreNCC backs U.K. Industrial Strategy for industry innovation scale-up

The U.K. government’s recently published economic approach aims to remove barriers and set a clear path toward growth opportunities in advanced manufacturing, aerospace, clean energy, defense and AI.

Read MoreCoriolis Composites introduces the C3 dockable AFP head

AFP solution for gantry and robot systems offers manufacturers enhanced flexibility, performance and ease of use for a wide range of composite parts.

Read MoreAutonomous agents optimize decision flows in aerospace, composites production

CAMX 2025: With manufacturers face labor shortages, increasing product complexity and pressure to operate sustainably, Plataine’s AI Agents provide the agility and intelligence needed for real-time decision-making.

Read MoreWichita State, Dassault Systèmes open Manufacturing Innovation Center

Aviation companies of all sizes will be able to improve their resilience and efficiency via the center’s virtual design, automation and additive manufacturing capabilities.

Read MoreFACC optimizes inspection processes through augmented reality

Cooperation with students from the University of Applied Sciences Upper Austria leads to successful use of AR, increasing the efficiency of components testing.

Read More