Thermoplastics

Innovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

Read MoreRe:Build Manufacturing acquires Composite Resources

Massachusetts-based investment group Re: Build Manufacturing has acquired South Carolina-based fabricator Composite Resources.

Read MoreDLR launches EmpowerAX to industrialize continuous fiber 3D printing

Global, industry-diversified platform will increase access to additive extrusion (AX) technologies and accelerate technology transfer for users and providers.

Read MoreStratasys carbon fiber material for 3D printer line is more functional, lightweight and versatile

ABS-based carbon fiber material for the Stratasys F123 Series 3D printer line is 15% stronger and 50% stiffer compared to standard ABS.

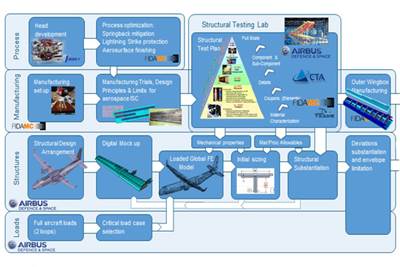

Read MoreIIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

Read MoreComposite radome design secures patent, overcomes signal attenuation challenges

Fiberglass skins with a closed cell thermoplastic foam supports the easy transmission of radio waves while offering signal antennae environmental protection.

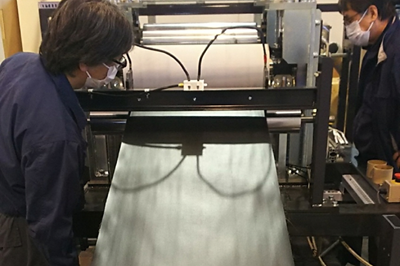

Read MoreMaruHachi installs new UD tape line for high-end applications

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

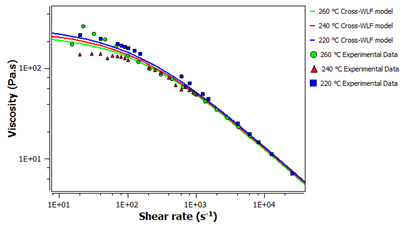

Read MoreThermoplastic tapes reinforced with textile-based PAN carbon fiber

IACMI project trials inline production of thermoplastic tapes reinforced with textile-based PAN carbon fiber.

Read MoreBilsing expands aerospace composites capabilities with 3D tape laying equipment

Conbility PrePro 3D system will be used to produce components for aircraft interior galleys, seats and overhead bins.

Read MoreGE to research AM for wind turbine blades

Twenty-five-month project to couple low-cost thermoplastic skin with AM for high-performance wind blade designs to be used on large rotors.

Read More