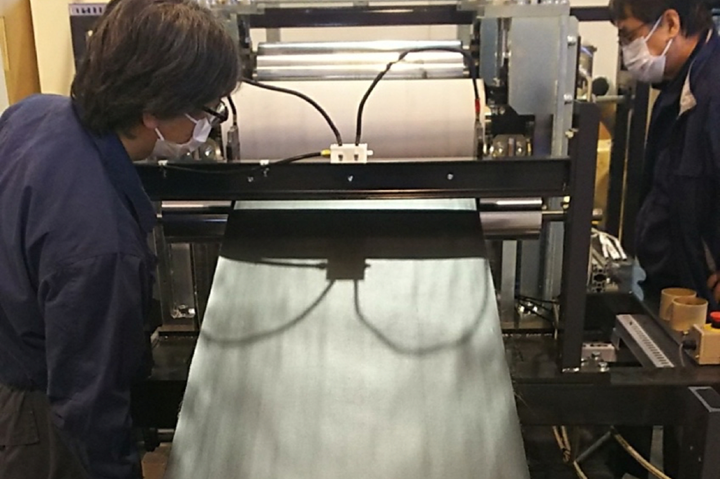

MaruHachi installs new UD tape line for high-end applications

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

Photo Credit: MaruHachi

With a recently installed high-temperature unidirectional (UD) tape line, composites manufacturer MaruHachi (Fukui, Japan) says it enables new opportunities for high-end applications in demanding market segments like aerospace, automotive, or others outperforming traditional materials based on polypropylene (PP) and PA.

With a more specific focus on high-temperature thermoplastic UD tapes and multi-layer sheet laminates, MaruHachi says it will produce up to 40 tons per year in the first phase. The material is based on high-performance fibers— carbon, aramid, glass, or natural fibers — with a high-performance polymer matrix — PPS, PEEK, or other high-temperature polymers — which are tougher than epoxies and easy to recycle. With a width of 500 millimeters, and a specific weight ranging from 60-350 grams per square meter, MaruHachi says the lines can operate under temperatures up to 420ºC, depending on the material chosen. The results include better material properties, higher performance, increased resistance and integrated high-performance functionalities (e.g. by overmolding).

Since 2017, MaruHachi Group has been active in the European market in cooperation with Dr. Michael Effing,the CEO of AMAC GmbH (Aachen, Germany), who advises and supports the company strategically. The established, family-owned MaruHachi Group has a history in automotive and medical textiles, and has been active in the innovative composites market for more than 15 years.

“For many years, we have been cooperating with domestic and international partners on high-demand applications and because of this, MaruHachi decided to invest over €1 million in this new line in phase one, including a funding participation from the Japanese government NEDO,” says Toshi Sugahara, CEO of MaruHachi. “New developments in phase two will be undertaken by the end of 2021 on downstream technologies, including automated preforming and consolidation. With our new products, we want to contribute to significant weight reductions of the final products, thus improving energy efficiency while offering a cost-efficient and high-quality solution.”

Dr. Effing, CEO of AMAC GmbH confirms: “The focus on high-temperature products based on PPS and PEEK enables MaruHachi to develop materials for very demanding high-end applications such as structural frames, aircraft seats, engine components, etc. The tapes are fully recyclable and can be processed [with high-speed, laser-based tape placement machines and robots].”

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.