Thermoplastics

Complex recycled CFRTP parts demonstrate discontinuous fiber advantages

CAMX 2023: herone GmbH is showcasing a set of tubes, shafts and profiles, all of which demonstrate the feasibility of rCF discontinuous fibers molded into complex thermoplastic composite parts.

Read MoreThermoplastic honeycomb, lightweight solar modules demonstrate sustainability

CAMX 2023: Together, EconCore and ThermHex are providing a first look at new product variations for additional lightweight opportunities, including high-performance thermoplastic cores and solar panels with a honeycomb structure.

Read MoreBespoke thermoplastic composite solution services

CAMX 2023: Svismold invites CAMX attendees to witness how it is redefining the design and production of thermoplastic composites.

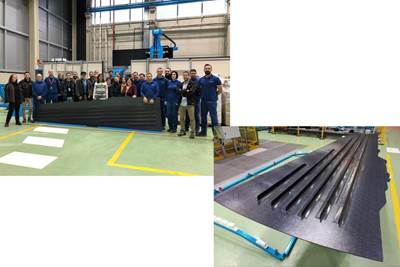

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

Read MoreINN-PAEK project succeeds in 100% recyclable turbine

European project replaces complex-shaped metal structure in aircraft cooling system with injection molded thermoplastic composite material for improved sustainability.

Read MoreAitiip Technology Center reports dismantling of thermoplastic parts using resistance welding

Clean Sky 2 HELACS project aims to enable improved recycling of composite components at aircraft end of life.

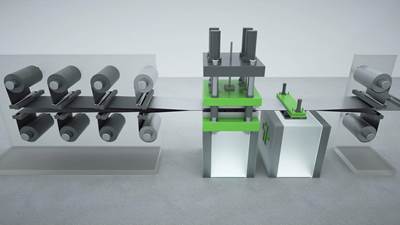

WatchProcess method enables continuous particle foam production

CAMX 2023: Infinite Hybrid, a technology from Foam Equipment & Consulting Co., enables continuous production without secondary operations.

Read MoreAFPT, Alformet advance bending of thermoplastic composite tubes

Specialists in AFP and LATW discuss process and lessons learned for new applications in CFRTP parts.

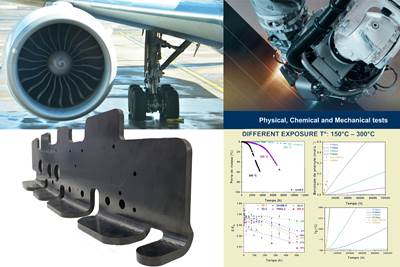

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

WatchOptimized approach to predict delamination failure in CFRTP structures

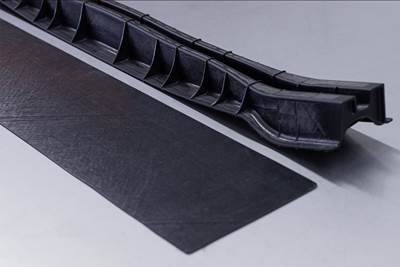

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read More