Process method enables continuous particle foam production

CAMX 2023: Infinite Hybrid, a technology from Foam Equipment & Consulting Co., enables continuous production without secondary operations.

Photo Credit: Foam Equipment & Consulting Co.

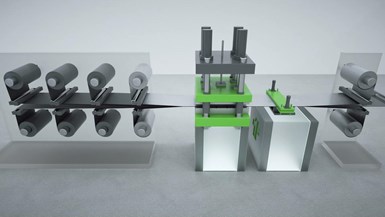

The Infinite Hybrid method, from (Earth City, Mo., U.S.), enables the continuous production of particle foam and sandwich components, offering a multitude of applications across various sectors. Particle foam is based on thermoplastic polymers and consists of over 90% air, which makes it well-suited for lightweight applications. In contrast to conventional manufacturing methods where individual parts are produced separately and then assembled, Infinite Hybrid enables the continuous production of components.

The technology is based on the combination of Atecarma and Teubert continuous compression molding (CCM) technology. The particle foams are treated with Atecarma activator in advance. The materials, with or without sandwich layers, are automatically fed into the CCM machine, where they are compacted, heated, cooled, stabilized and demolded step by step. By employing high precision tools and advanced control systems, Infinite Hybrid can create flat panels and sandwich components in just one production step without the need for secondary operations.

In addition to continuous production, the company says Infinite Hybrid also offers other benefits, including weight reduction, cost efficiency and design freedom. By using particle foam, components with lower density can be produced. This results in a reduction in weight for components, particularly in the automotive and aerospace industries. Through continuous production, costs associated with tool changes and the assembly of individual parts are minimized, leading to more efficient manufacturing processes and reduced production costs. Design freedom is made possible through Atecarma. Complex combinations of different materials are said to be more easily achieved, providing the opportunity for innovative and aesthetically pleasing products.

The company says that Infinite Hybrid technology has the potential to fundamentally transform the way components are manufactured and used. Through the benefits it provides in weight reduction, cost efficiency and design freedom, it can expands perspectives across industries.

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.