Sustainability

Measuring and improving fire resistance in composites

Sidebar to CW’s Feb 2019 feature article, this quick review of fire tests for composites also provides more details about intriguing new material developments.

Read MoreBoeing, Aerion partner on supersonic air travel

Boeing to provide engineering, manufacturing and flight test resources to bring Aerio’s AS2 supersonic business jet to market.

Read MoreGoing discontinuous, for continuous improvement

The HiPerDiF (High Performance Discontinuous Fibre) project is exploring an alternate way of producing high-performance carbon fiber composites: start with discontinuous, rather than continuous fibers.

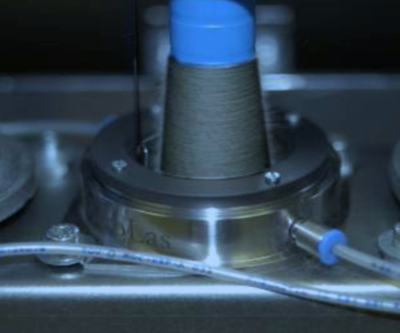

WatchAeroLas explores new spinning technology for thermoplastic hybrid yarn

AeroLas is working to combine recycled carbon fiber with PEEK using adapted art textile machines and a patented air guided ring spinning technology.

WatchWithstanding fire without the weight

New composites meet stringent fire requirements while lightweighting ships, rail cars and battery boxes for electric cars and planes.

Read MoreFoiling motoryacht impresses in carbon fiber/epoxy

A project is underway to build a faster, lighter, hybrid-electric motorboat with foils and hull fabricated from carbon fiber and epoxy.

Read MoreBally Ribbon Mills acheives ISO 13485:2016 certification

Bally Ribbon Mills (BRM, Bally, PA, US), manufacturer of specialized engineered woven fabrics, has received ISO 13485:2016 certification.

Read MoreMichelman opens sustainability center in Shanghai

The Michelman Sustainability Center is focused on reinforcing green manufacturing and will help the company better adapt its products and services to the Chinese market.

Read MoreCOBRA International supports river clean up campaign in Thailand

The composites manufacturer recently donated 10 lightweight kayaks to the recent Kayaking for Chao Phraya River clean up mission.

Read MoreAMRC and Prodrive partner to advance manufacturing of recyclable composite components

The companies have been collaborating on Prodrive’s P2T process, which is used for manufacturing recyclable composite components that can satisfy end-of-life requirements without any compromise in the performance of the original parts.

Read More