Processes

Swinburne-CSIRO Testlab grows composites competency via industrial-scale 3D printing

Industry 4.0 facility is integrating an additive manufacturing approach to its holistic processes to optimize composite component production rates, quality and cost.

Read MoreECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreMARS Center grows LFAM capabilities with JuggerBot 3D Tradesman Series

P3-44 pellet-fed 3D printer is capable of leveraging a range of fiber-reinforced composite materials, to be used for the production of high-fidelity components in aerospace and defense.

Read MoreCEAD, Adaxis launch “AdaOne for Flexbot” software integration

Collaborative effort results in a software experience that seamlessly integrates with CEAD’s Flexbot systems, aiming to elevate the efficiency in robotic large-format 3D printing with composites.

Read MoreCarbon Conversions offers 3D printing filament reinforced with rCF

Development of re-Evo TDR products that work on a majority of 3D printers is now an available option for companies sending in their carbon fiber waste.

Read MoreAirtech, Caracol grow LFAM with Dalhtram resins, Heron AM pairing

New partnership will see Dahltram resins qualified for integration with Caracol’s Heron AM platform.

Read MoreMassivit, Sika to co-brand digital tooling materials for Massivit 10000 series

Strategic MOU initially introduces SikaBiresin CIM 120 and SikaBiresin CIM 80 to serve crucial composites market needs for 3D printing tooling, prototyping and more.

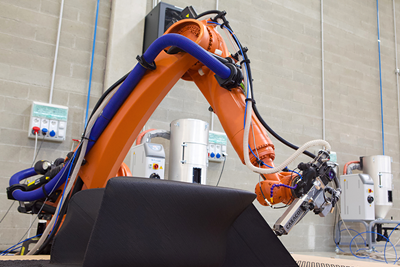

Read MoreBelotti to integrate hybrid BEAD system with Adaxis AdaOne software

Through this strategic collaboration, BEAD’s additive and subtractive capabilities for large-scale AM composite tooling production are made more accessible.

Read MoreCMS, Caracol collaboration targets large-format 3D printing market

Global development of LFAM technologies and applications will support end user’s adoption of 3D printing for composites.

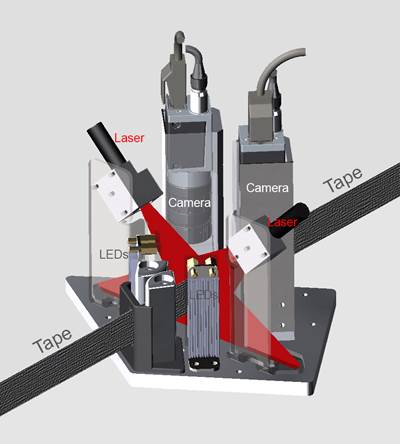

Read MoreDaQoTa project develops measuring head prototype for LATW inspection

Fraunhofer IPT, Taniq and Pixargus have proven the success of a measuring head capable of optimizing the reliability, security and efficiency of FRP pressure vessel manufacturing.

Read More