Processes

Highlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreAonix Advanced Materials system combines material, machinery

Ottawa-based company develops turnkey technology for high-performance, thermoplastic composites at volumes of up to 1 million parts per month.

Read MoreComposite flywheels: Finally picking up speed?

A wave of new composite flywheel developments for bus, rail, auto, heavy truck, construction equipment, and power grid support promises fuel savings, improved efficiency and reduced emissions — i.e. sustainability in the global quest for more energy.

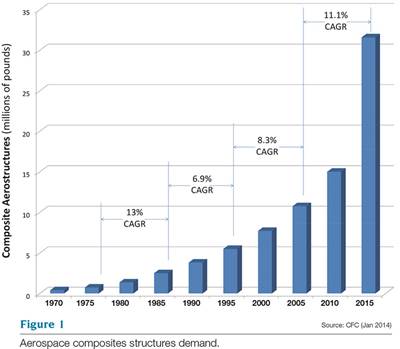

WatchThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

Read MoreNDI and NDT methods for process control

There are three main nondestructive inspection technologies currently under development to help qualify surface preparation techniques for adhesively bonded aerospace surfaces evaluate the quality of both the prepared surfaces and the final bonded joint.

Read MoreCertification of bonded composite primary structures

OEMs develop technology to quantify uncertainty in pursuit of the no-bolt bondline.

Read MoreNo-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

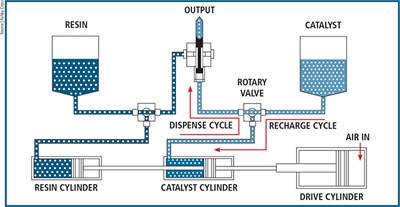

WatchMeter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

Read MoreSemipermeables: Next trend in infusion?

These liquid-blocking membranes promise molders better properties, less waste and reduced risk.

Read More