Processes

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

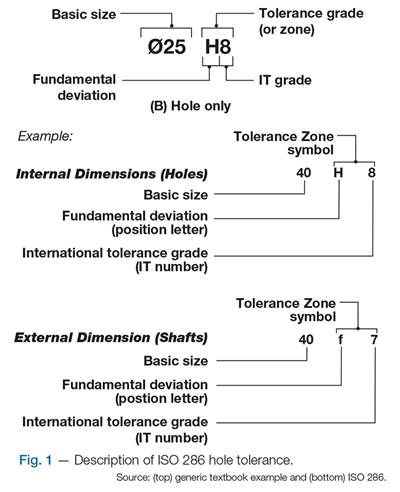

Read MoreHole quality defined

In the aerospace industry, drilled hole quality is defined by ISO 286: System of Limits and Fits, a coordinated system of hole and shaft tolerances that is used in both engineering and production.

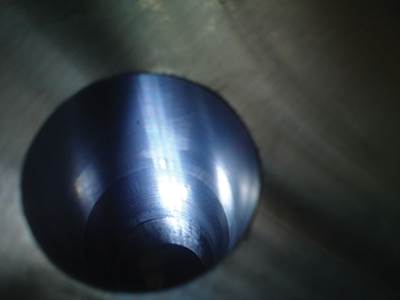

Read MoreMachining update: One-shot dry drilling of stacked materials

Tool design innovations tighten tolerances and cut costs for those who drill composite-metal assemblies.

Read More3D Printing continuous carbon fiber composites?

Additive manufacturing startup MarkForged aims to make it happen and is already marketing systems.

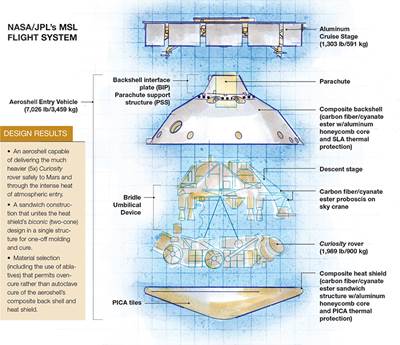

Read MoreComposites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreDon’t call it a blimp!

The builders of this variable-buoyancy craft count on carbon fiber/epoxy trusswork to enable a new era of air transport.

Read MoreSAMPE Tech Seattle 2014 at a glance

A short compilation of SAMPE Tech Seattle 2014 program highlights.

Read MoreSAMPE Tech Seattle 2014 Preview

The Society for the Advancement of Material and Process Engineering’s annual fall Tech conference is now a spring event.

Read MoreThe Learjet 85: Large step out of the autoclave

HPC editor-in-chief Jeff Sloan examines the significance of the Bombardier Learjet 85’s first flight.

Read MoreMove over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read More