Processes

IACMI Scale-Up Research Facility to host Compression Molding Workshop

Workshop aims to enable OEMs and fabricators seeking to expand composites penetration in automotive and other end markets.

Read More48th auto-plastics competition highlights changing industry

Additive manufacturing, autonomous vehicles, greener parts featured prominently.

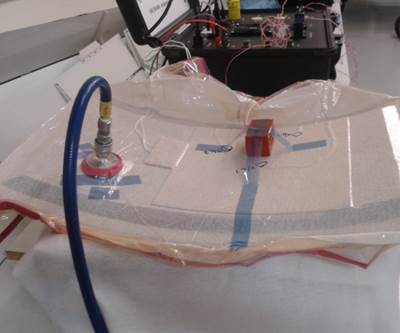

Read MoreMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Read MoreDiversified Machine Systems acquired by CMS North America

With the acquisition CMS broadens its portfolio of custom CNC machine solutions.

Read MoreBally Ribbon Mills offers film infusion for 3-D woven joints

In the film infusion process, a frozen sheet or film of resin is infused onto the custom 3-D woven joint, saving customers the trouble of infusing the resin themselves.

Read MoreRock West Composites opens Tijuana facility

New facility includes production areas for manufacturing processes including resin infusion, bladder molding, roll wrapping, wet layup and precision composite assembly.

Read MoreEastman Machine Co. achieves ISO 9001:2015 certification

ISO 9001 is the international standard that specifies requirements for a quality management system.

Read MoreBoeing and Thermwood

The Boeing Co. (Chicago, IL, US) and Thermwood Corp. (Dale, IN, US) have employed additive manufacturing technology to produce a large, single-piece tool for the 777X program.

Read MoreGKN Fokker to implement automated kitting solution from Airborne

The automated kitting solution is said to reduce costs by saving man-hours and material scrap, and it enabling a flexible and digital workflow.

Read MoreThermwood and US Navy explore additive manufacturing for ships and ship systems

The validation program centered on printing an unclassified scale nose of a submarine using Thermwood’s Large Scale Additive Manufacturing (LSAM) system.

Read More