Processes

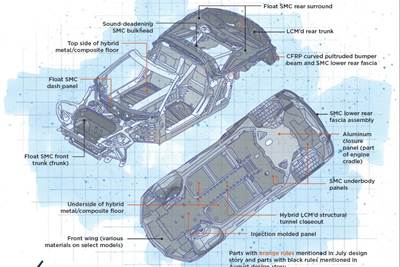

Composites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

Read MoreComposites Evolution introduces Evopreg EPC200 epoxy prepreg

Evopreg EPC200 enables variable temperature cure with good surface finish.

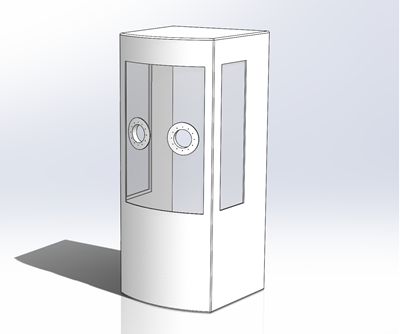

Read MoreFiberglass composites enable lighter, sturdier COVID-19 testing booth design

Canada-based Imagine Fiberglass’ IsoBooth station is designed to eliminate the need for PPE by healthcare workers testing patients for COVID-19.

Read MoreMagellan Aerosystem commits to Airborne automated kitting system

Manufactured by Airborne, the solution will support fabrication of composite horizontal tail assemblies for the F-35 fighter aircraft.

Read MoreConstruction of new Arevo composite 3D printing facility announced

The continuous fiber 3D printing specialist also named new executive leadership to support its growth plans.

Read MoreSatellite deployer redesign supported by 3D-printed composites

A Scottish technology company employs additive manufacturing and CRP Technology composite materials for a lighter, more manufacturable PocketQube deployer.

Read MoreAscent Aerospace invests in large-format AM machine

The LFAM machine will enable fabrication and delivery of production-ready fixtures and molds at significantly reduced lead-times.

Read MoreComposites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreCoriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

Watch