Processes

Strata to manufacture compression-molded components for Pilatus PC-24

Strata to deliver composite engine mounting flaps, as well as the horizontal flap and conical stabilizer of the aircraft's tail per a seven-year deal.

Read MoreWEAV3D, GAA partner to expand structural composite opportunities in automotive sector

Tunable, composite lattice structures produced via patented automated weaving process able to support automotive volumes of hundreds of thousands of units per year.

Read MoreCobra International commissions prepreg compression molding production line

Production capacity delivers highly structural prepreg carbon fiber hydrofoil components with a final surface finish straight from the mold.

Read MoreContinuous Composites demonstrates CF3D technology for Lockheed Martin, AFRL WiSDM project

Continuous Composites carbon fiber wing spar structural performance achieves 160% design limit load with no damage detected, offers potential for aerospace-grade composite printing.

Read MoreWSU-NIAR adds automated TP welding and tape-slitting capabilities to ATLAS facility

Systems to aid in welding process developments for the joining of composite structures via fusion bonding, and support AFP demands.

Read MoreThermwood completes first LSAM 1010 system

Large-scale additive manufacturing system simultaneously prints and trims via a single, large gantry and offers speeds up to almost three feet per second.

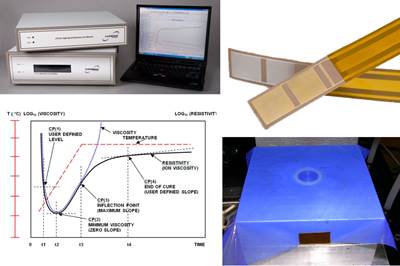

Read MoreCombining AC and DC dielectric measurements for cure monitoring of composites

Lambient Technologies advances dielectric analysis (DEA) for more reliable, affordable composites manufacturing.

Read MoreFACC successfully develops novel composite flap system for Wing of Tomorrow

RTM’d five-meter-long, complex multicell flap prototype constructed via a highly integral, cost-effective manufacturing process.

Read MoreImpossible Objects, Ricoh 3D partner to produce high-strength 3D-printed composite parts

New material options for industrial customers across Europe to remove barriers to printing parts for drones, aircraft, automobiles, athletic gear and more.

Read MoreBorflex releases compacting AFP roller range

Applicable to thermoset or thermoplastic prepregs, the Fiberroll compacting roller range ensure optimal surface appearance, rugosity and geometry while avoiding material adherence.

Read More