PEKK

TPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

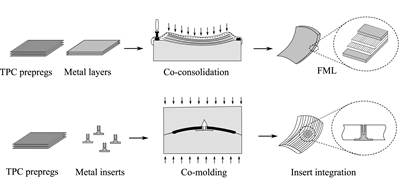

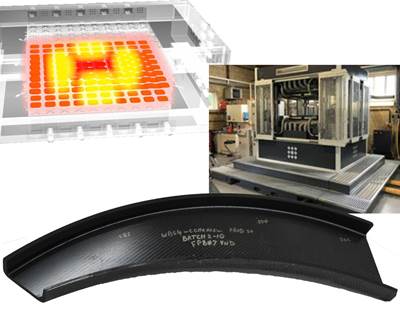

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Read MoreHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreHexcel applies additive manufacturing to unmanned aerial vehicle systems

Hexcel’s HexAM process produces stiff, lightweight and complex components that are often too expensive or impossible to produce.

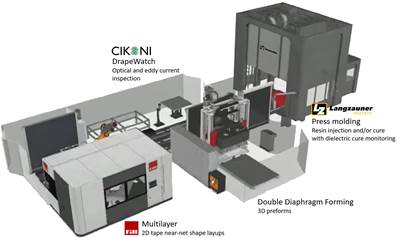

Read MoreSwinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

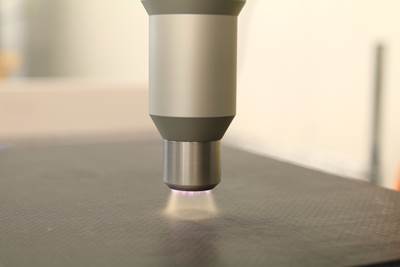

WatchSurface treatment for adhesive bonding: Thermoset vs. thermoplastic composites

According to BTG Labs, common surface treatment methods like abrasion and plasma treatment work best for different materials.

Read MoreThe untapped potential in Formula 1 composite manufacture

Formula 1’s midfield teams are struggling to bridge the gap to their better resourced frontrunning counterparts. Could Industry 4.0 composites manufacturing automation level the playing field?

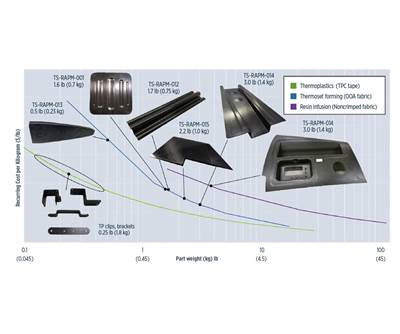

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

Read More