Out of Autoclave

IACMI Scale-Up Research Facility to host Compression Molding Workshop

Workshop aims to enable OEMs and fabricators seeking to expand composites penetration in automotive and other end markets.

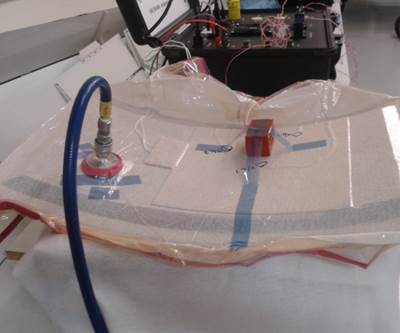

Read MoreMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Read MorePlant tour: Composite Resources, Rock Hill, SC

Equipped to meet vertical needs with rapid turnaround, Rock Hill, SC’s Composite Resources has found the sweet spot between prototypers and large composites manufacturers.

Read MoreBally Ribbon Mills offers film infusion for 3-D woven joints

In the film infusion process, a frozen sheet or film of resin is infused onto the custom 3-D woven joint, saving customers the trouble of infusing the resin themselves.

Read MoreRock West Composites opens Tijuana facility

New facility includes production areas for manufacturing processes including resin infusion, bladder molding, roll wrapping, wet layup and precision composite assembly.

Read MoreVeelo Technologies expands operations

New facility to support demand for lightning strike protection and EMI shielding, electro-thermal deicing, and heating solutions for composite repair and out-of-autoclave/out-of-oven composite manufacturing.

Read MoreIf you didn't make it to CAMX, here's what you missed

CAMX 2018 was held Oct. 15-18 in Dallas, and if you could not attend this year, ÂÌñÏ×ÆÞ did it for you. This compendium of written and video reporting from the show is designed to bring you up to speed on the new products, trends, presentations and more that the show had to offer.

Read MoreAVK presents its 2018 Innovation Awards

The 2018 AVK Innovation Awards were presented at the International Composites Congress (ICC) on Nov 5, chosen from more than 50 submissions.

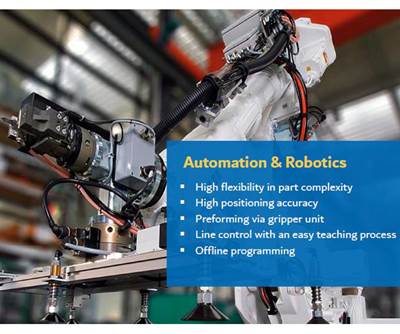

WatchAutomating composites production for ease of use and affordability

Schmidt & Heinzemann innovates composites workcells with German quality and small-company flexibility — “modules customized per product and program is the key.”

Read MoreDowAksa joins wind blade consortium PULLWind

DowAksa has joined the group with the aim of helping clients to build and develop their businesses in relation to the use of carbon fiber for wind turbine blade manufacture.​​​​​​​

Read More