Out of Autoclave

Tooling boards improve processes

In the composites industry, many parts are the product of one-off or few-of-a-kind production programs. In response, tooling material suppliers today provide an increasing variety of relatively inexpensive materials grouped under the heading of tooling board.

Read MoreSAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

Read MoreJEC Paris 2011 Review

This annual Paris trade event’s statistics signal an advanced composites resurgence.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

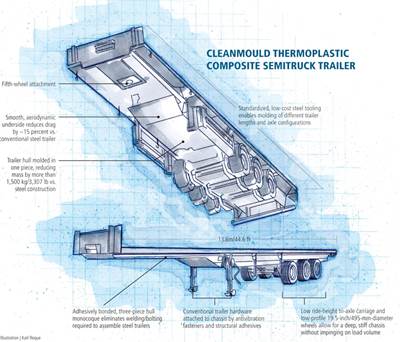

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read MoreTough resins for aggressive environments

New thermoset systems drive composites deeper into markets where fire, corrosion, stress and fatigue are ever-present threats.

Read More3-D preforms: Fast, efficient blade-root manufacture

To expedite the blade root manufacturing process for wind turbine blade manufacturers, 3TEX Inc. (Cary, N.C.) has developed RapidRoot, a 3-D preform.

Read MoreHeavy-duty infusion: Scaling up for scrubbers

Infused 3-D woven fabric preforms best steel in beams and unitized deck structures built for the caustic confines of massive flue gas desulfurization systems.

Read MoreQ&A: Manuel Torres Martinez

At the 2011 JEC Composites Show in Paris, CT had the opportunity to interview MTorres Group chairman Manuel Torres Martinez, excerpts from which appear here.

Read MoreTraining surge: Too little, too late?

Hands-on programs are aimed at younger students by educators hoping to prevent shortages of composites technicians and engineers.

Read More