Out of Autoclave

No-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

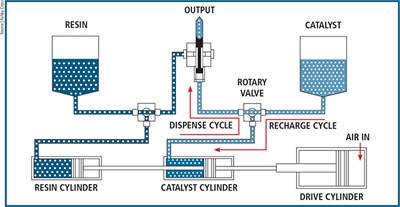

WatchMeter/mix/dispense machines: The suppliers and systems

HPC’s meter/mix/dispense (MMD) roundup includes this collection of the principle suppliers of MMD equipment and equipment characterizations.

Read MoreMeter/Mix/Dispense Machines: Balancing speed and control for auto CFRP

Suppliers of meter/mix/dispense (MMD) equipment are under pressure to keep pace with process innovations that are drastically reducing mold cycle times for carbon fiber/epoxy laminates in automotive applications.

Read MoreMeter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

Read MoreSemipermeables: Next trend in infusion?

These liquid-blocking membranes promise molders better properties, less waste and reduced risk.

Read MoreSportfishing yacht: Infusion optimized

This well-loved deepsea fishing brand has moved from Miami to a new facility, and to a state-of-the-art resin-infused laminate for its Bertram 64.

Read MoreFossil and mineral resources: Composites expand

Attention-grabbing applications in these challenging, corrosive environments are positioning fiber-reinforced polymers for continued growth.

Read MoreBuilding a stronger longitudinal leaf spring

Benteler-SGL (Ried, Austria) has identified a carbon fiber hybrid system for production of longitudinal springs.

Read MoreComposite leaf springs: Saving weight in production

Fast-reacting resins and speedier processes are making economical volume manufacturing possible.

Read MoreLegacy applications: Inspiration for future vehicles?

Dale Brosius, a consultant and president of Quickstep Composites (Dayton, Ohio), looks back at past automotive composites applications for today's market opportunities.

Read More