Materials

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreApply Carbon establishes mass recycled carbon fiber production facility

Apply Carbon has completed the commission of a fully automated production plant for recycled carbon fibers, with an estimated capacity of 4,000 metric tons.

Read MoreBMComposites, Linx Tenders use composites to lighten foiling cats

Glass and carbon fiber meet performance needs for custom-built tenders.

Read MoreRecycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

Read MoreEvonik showcases chopped carbon fiber-reinforced PEEK filament

Vestakeep is available at two levels of carbon fiber content and appropriate for long-term surgical implants.

Read MoreSicomin epoxy resins power Candela composite boat construction

Candela’s zero-emission P-12 foiling passenger shuttle offers low vessel weight, higher journey frequency with its carbon fiber-reinforced epoxy fabrication.

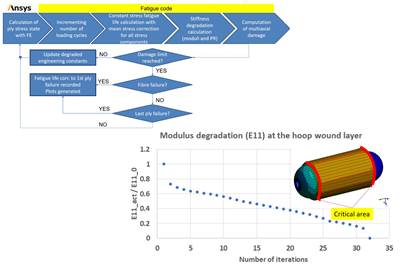

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read MoreMikrosam filament production line supports Amargo tank production

Mikrosam system features will support the production of Amargo’s chemically resistant pressure vessels or hydrogen storage in industrial plants.

Read MoreBeSpline wins IBEX Innovation Award, announces partnership with Boston Boatworks for Shaped Foam Kits

CAD-driven fabrication uses adaptive mold technology for lighter, stronger, higher quality boat structures without time and cost of building a mold while drastically reducing core fitting time for yacht builders.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read More