Materials

New MIL antiballistics standard

New military specifications for unidirectional thermoplastic laminates used in antiballistics applications are circulating in draft form for comments and should be completed by year’s end.

Read MoreHybrid Enhanced Combat Helmet enters final testing phase

The U.S. Army and Marine Corps are conducting final validation testing of the U.S. military’s next-generation — and radically new — thermoplastic composite Enhanced Combat Helmet (ECH).

Read MoreBuilding on CCM lessons learned

Knowledge gained during NASA's composite crew module (CCM) program, a sidelight to the Orion space capsule program, now benefits private space efforts.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

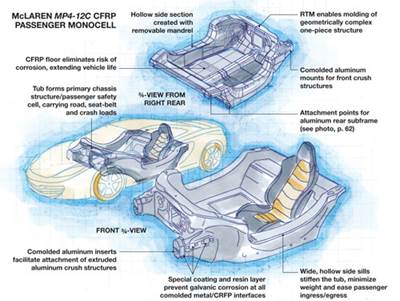

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreBlades? Yes! Towers ... maybe

Although steel dominates the utility-scale wind turbine tower market, height increases, on- and offshore, are shifting the wind toward composites.

Read MoreLightweighting a heavyweight

Process combination produces significantly lighter overhead storage bins for big-rig sleeper cabs.

Read MoreThe green challenge

Hugo Giffard, engineer and continuous improvement manager at LM Wind Power (Canada) Inc. (Gaspé, Quebec, Canada) discusses the need for recycling partners in his company's efforts to deal responsibly with waste glass-fiber reinforcements.

Read MoreInterior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

Read More