Materials

Tires that never go flat

SciTech Industries and Rapid Composites develop high-volume production tires that use glass fiber/PET composite springs instead of innertubes and compressed air.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read MoreThermoplastic composites: European consortia, galore!

In addition to the Thermoplastic Composites Research Center (TPRC, Enschede, The Netherlands) — see our article focused on TPRC, titled "Thermoplastic composites technology: A view from Europe" under "Editor's Picks, at top right — there are many other European consortia, comprising private industry, university and government entities, which share the goals of exploring composites materials and methods for manufacturing them, including those with thermoplastic matrices. Here's a sampling.

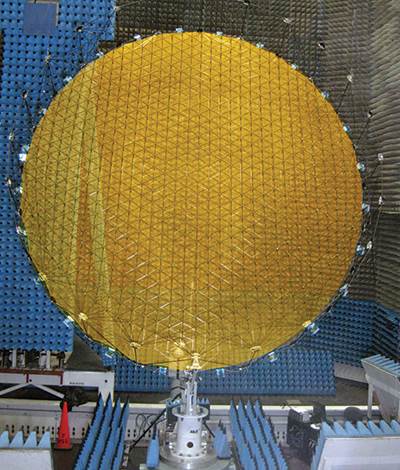

Read MoreIn-orbit-deployable radar dish

Aramid/PEI delivers flexibility, strength and precision for space-based reflector

Read MoreFirst all-carbon yacht a winner

Vacuum infusion with customized fabrics enables demanding yacht build

Read MoreUnderstanding the influence of fiber orientation on structural analysis of fiber-filled parts

The effect of fiber orientation on material properties is a key way the injection molding process impacts mechanical performance. Doug Kenik and Angie Schrader of the Design, Lifecycle & Simulation product group at Autodesk (Waltham, MA, US) illustrates two ways fiber orientation influences the structural behavior of fiber-filled parts and discuss the need for a bi-directional approach to design and analysis.

Read MoreRevisiting some past perspectives

CW columnist and composites-industry consultant Dale Brosius takes a look back at some past "Perspectives & Provocations" columns with an eye to how the perspectives then match up with the realities of today's high-performance composites market.

Read MoreSFMOMA façade: Advancing the art of high-rise FRP

The fabrication and installation of 700+ composite panels has a backstory of detailed design and careful quality assurance.

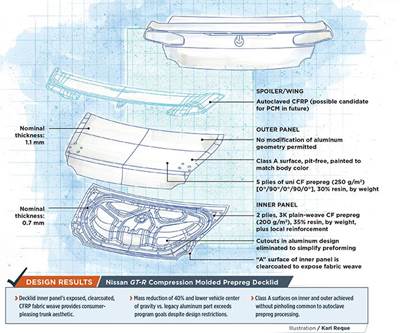

Read MorePrepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

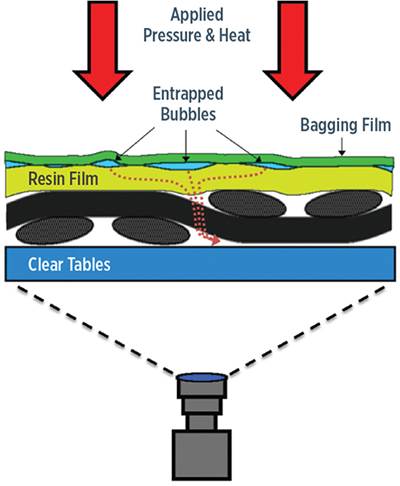

Read MoreOut-of-autoclave processing: <1% void content?

Research sheds light on air and air-bubble behavior in OOA aerospace prepregs.

Read More