Materials

CompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

Read MoreDemonstrating recyclable, bio-based autocomposites

The ECOXY research consortium recently developed a demonstrator automotive part constructed from recyclable flax fiber and a specialized bio-based epoxy.

Read MoreCAMX 2020 announces conference program and keynote speaker

Presentations from Microsoft, Uber Elevate, BFG International, Joby Aviation, Anzac Contractors, the Florida DOT will be featured at CAMX 2020.

Read MoreComposite sandwich panels enable flexibility in medical table design

Polyurethane foam core provides a cost-effective option for ACP Composites’ specialized medical positioning table design.

Read MoreCollaborative R&D project aims to develop nanocomposite material for interior aircraft application

Pioneered by AIM Altitude, Sheffield Hallam University and Composite Evolution, the thermosetting resin system has resulted in cured prepregs showing improved fire properties.

Read MoreUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

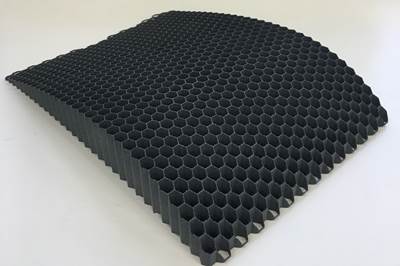

WatchHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreAustralian start-up builds first recycled carbon fiber composite surfboard

Juc Surf uses 100% recycled carbon fiber scrap materials for a more sustainable surfboard that doesn’t sacrifice performance.

Read MoreRhode Island boat recycling program plans expansion to other states

Having recycled 60 tons of fiberglass in two years, the RIMTA program will expand to Conn., Mass., Maine and Wash. state via funding from the NOAA Marine Debris Program.

WatchBreakThru Technology reduces free formaldehyde in phenolic resins

The technology reduces free formaldehyde in phenolic fiber-reinforced plastic (FRP) resins to below 1000ppm (less than 0.1%).

Read More