BreakThru Technology reduces free formaldehyde in phenolic resins

The technology reduces free formaldehyde in phenolic fiber-reinforced plastic (FRP) resins to below 1000ppm (less than 0.1%).

Georgia-Pacific Chemicals

New BreakThru Technology launched by Georgia-Pacific Chemicals (Atlanta, Ga., U.S.) is said to have been shown in laboratory testing to reduce free formaldehyde in phenolic fiber-reinforced plastic (FRP) resins to below 1000ppm (less than 0.1%). The company notes that the technology shows promise for a variety of industrial applications by potentially meeting or exceeding standard phenolic resin performance at lower residual monomer levels for both water and solvent-soluble resins.

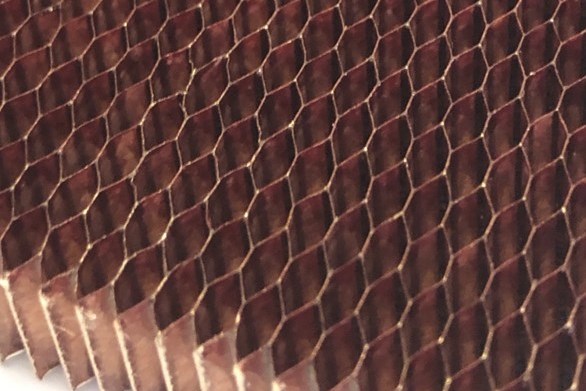

According to the company, reducing residual formaldehyde content in phenol-formaldehyde resins (phenolic resins) is a frequent request in composites and other industries. Phenolic resins used for industrial applications, such as abrasives, filtration, honeycomb, foaming, etc., historically contain free formaldehyde levels ranging from 0.3% to greater than 1.5%.

Georgia-Pacific Chemicals’ analysis also shows that free phenol levels are reduced with BreakThru technology and that resins have a faster curing profile. In addition, a honeycomb composite compressive strength study suggested improved performance in those applications.

Analytical studies of this technology will be presented as a technical paper at CAMX September 21-24, 2020 by Carlos Maldonado, senior development chemist, Georgia-Pacific Chemicals. They will compare the new technology with a commercially-available phenolic resin via thermal analysis, gas phase chromatography and high-performance liquid chromatography.

Georgia-Pacific Chemicals will also be featuring BreakThru technology at the Virtual CAMX conference September 21-24, 2020.

Related Content

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Aurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.