Machining/Drilling

Top 10 Considerations When Buying a CNC Machine for Composites

For a CNC machine to continue to meet or exceed a company’s needs, it must be built and spec’d with these needs in mind.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read MorePlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read MoreArtificial intelligence optimizes CNC milling of carbon fiber-reinforced composites

The Augsburg AI Production Network — DLR Center for Lightweight Production Technology (ZLP), Fraunhofer IGCV and University of Augsburg — use ultrasonic sensors to correlate sound to quality in composites machining.

Read MoreCAMX 2021 exhibit preview: Autonational

Autonational highlights its capabilities in automated filament winding and CNC machining, including a recent case study from a utility vehicle manufacturer.

Read MoreCAMX 2021 exhibit preview: Europe Technologies

Europe Technologies highlights its robotic finishing cells and ultrasonic cutting solutions.

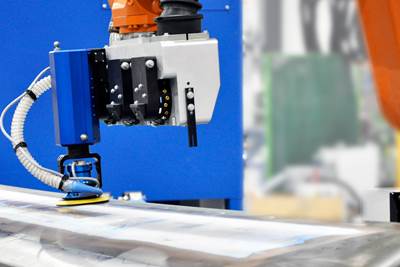

Read MoreGE, LM, NREL complete successful automated blade finishing trials

Pilot project started in 2020 leverages knowledge of advanced composites processing together with sensing, robotics and automation for low-cost solutions to boost throughput by 30%.

Read MoreLeuco PCD cutting tools enable high surface quality with long tool life

Leuco’s pure diamond milling, drilling and cutting tools achieve surface and durability requirements for CFRP automotive and aerospace components.

Read MoreVirgin Orbit automates composites machining processes for LauncherOne rockets

Part of the company’s larger strategy for reducing cycle times and labor costs on its composite-intensive rockets, a customized machine center from Multiax America solves composite machining challenges.

Read MoreUniversity of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Read More