Machining/Drilling

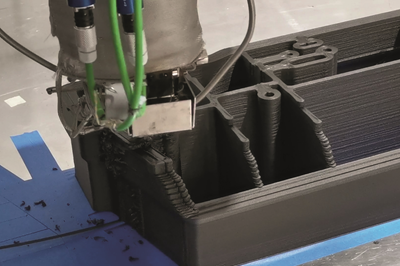

CMS debuts hybrid LFAM/milling machine

The machining specialist has developed the first iteration of Kreator, a large-format, thermoplastic composite 3D printer and five-axis milling machine for tooling and jigs.

WatchOerlikon Balzers launches new line of diamond coatings

Oerlikon Balzers has introduced its new Baldia portfolio of diamond coatings machining and drilling highly abrasive materials.

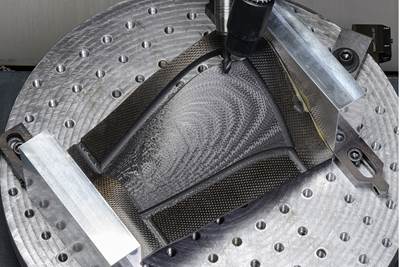

Read MoreCEAD and Belotti make large-scale additive composites manufacturing accessible for industry

Strategic partnership combines expertise of additive and subtractive manufacturing into single hybrid solution: BEAD.

Read MoreNorthrop Grumman contributes key composite structures for ULA Delta IV rocket launch

Eleven composite structure such as composite thermal shields, interstage, payload, propellant tanks, produced via hand layup, machining and inspection techniques supported the successful launch.

Read MoreBest practices in the CNC machining of composites

Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable.

Read MoreFraunhofer IPT automates production of thermoplastic CFRP engine fan blades

Successful first demonstrations on 16-mm-thick CF/PA12 to be followed by CF/PEEK tapes and embedded sensors for structural health monitoring (SHM).

Read MoreFraunhofer IFAM automates pre-assembly of CFRP fuselage frames

Positioning and drilling end effector for automated, high-precision and quality-assured pre-assembly developed with Airbus in German-funded “Tempo” sub-project.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

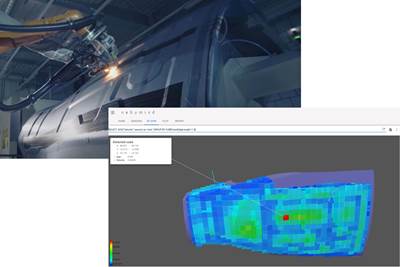

Read MoreUsing sensor data to improve composite parts and processes

nebumind software builds digital twins from manufacturing data to trace defects, compare manufactured parts, qualify processes, develop tolerance windows for process monitoring and more.

WatchCRP Technology produces composite sensor housing box

Commissioned by IMAL s.r.l., CRP applied its carbon fiber-reinforced Windform XT 2.0 material, which retains an 8% increase in tensile strength and 22% increase in tensile modulus.

Read More