Ketones

Building a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

Read MorePressurized Water-based mold temperature control comes to composites

HPC editor-in-chief Jeff Sloan details recent testing that gauged the comparative efficiency of electric, oil-based and water-based mold temperature control systems.

Read MoreHigh-temp thermoplastics: Higher Expectations

As the drive to greater fuel efficiency under the hood catches fire, fiber-reinforced thermoplastics prove they can take the heat.

Read MoreComposites in Aircraft Interiors, 2012-2022

As economic conditions improve and new programs come online, aircraft interior manufacturers are ramping up composites production to meet airline demand.

Read MoreThermoplastic Wind Blades: To be or not?

Will future wind blades incorporate thermoplastic composites? It depends on whom you ask.

Read MoreBig parts? Big tooling breakthrough

Electrically heated carbon fiber/PEEK/ceramic tooling and powdered epoxy resin system could revolutionize production of large composite aerospace structures.

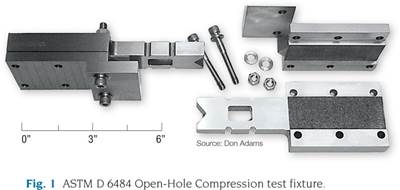

Read MoreTesting the damage tolerance of composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) looks at standards and also-rans in the area of testing for damage tolerance.

Read MoreForged composites replace complex metal parts

Powerhouse manufacturer’s high-pressure compression molding process forms prepregged CFRP components with forged-metal properties.

Read MoreReinforced engineered polymer selected for cargo door fastener

On a major new commercial aircraft program, self-fixturing nut-plates provided by Click Bond (Carson City, Nev.) eliminate the need for special tools, clamps and drills, expediting the process of installing attachment bracket hardware.

Read MoreSAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

Read More